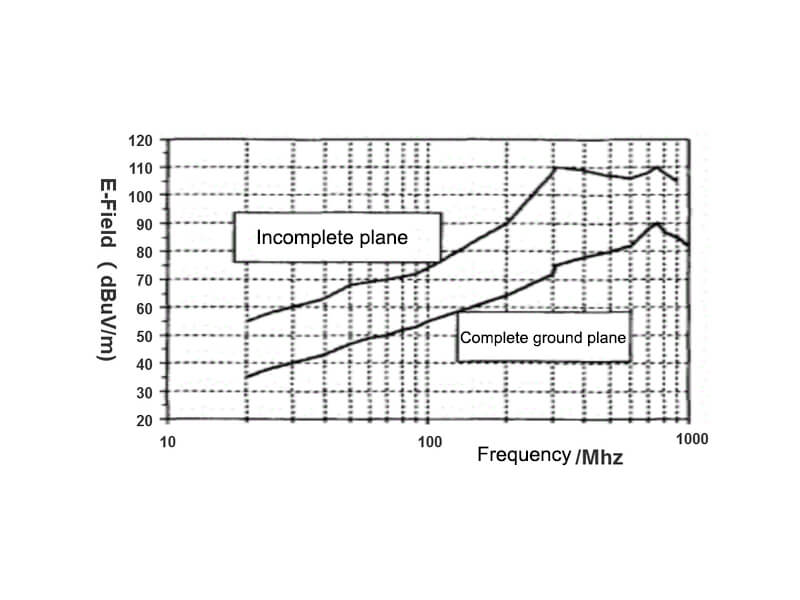

With the development of science and technology, especially in the advancement of the materials of integrated circuits, the computing speed has been significantly improved, which has led to the development of high-density, small-volume, and single-component integrated circuits, which all lead to today’s and future printed circuit boards. The application of high-speed digital circuits, that is, it is necessary to control the impedance of the line, low distortion, low interference, and low crosstalk and eliminate electromagnetic interference EMI. Impedance design is becoming more and more critical in PCB design. As the front-end part of PCB manufacturing, it is responsible for the simulation calculation of impedance and the design of impedance strips. Customers have stricter and stricter requirements for impedance control, and the number of impedance controls has also increased. How to design impedance quickly and accurately is a problem that pre-production personnel is very concerned about.

What is Impedance?

Impedance Definition: The total resistance to an alternating current of a known frequency flowing through it is called impedance. For printed circuit boards, it refers to the total impedance of a circuit layer (signal layer) to its closest related layer (reference plane) under high-frequency signals.

Impedance Type

- Characteristic impedance In electronic information products such as computers and wireless communications, the energy transmitted in the circuit of the PCB is a square wave signal (called pulse) composed of voltage and time. The resistance encountered is called the characteristic impedance.

- Differential impedance Two identical signal waveforms with opposite polarities are input to the driving end, respectively transmitted by two differential lines. The two differential signals are subtracted at the receiving end. The differential impedance is the impedance Zdiff between the two wires.

- Odd-mode impedance The impedance Zoo of one line to the ground in the two lines, the impedance value of the two lines is the same.

- Even-mode impedance Zcom is when the two signal waveforms with the same polarity are input to the drive end, and the two lines are connected.

- Common mode impedance The impedance Zoe of one line to the ground in the two lines, the impedance value of the two lines is the same, usually more significant than the odd mode impedance.

Characteristics and differential are typical impedances, and standard and odd modes are rare.

Factors Affecting Impedance

W—–line width/line The impedance becomes smaller as the line width increases, and the impedance increases as the distance increases;

H—-Insulation thickness The thickness increases, and the impedance increases;

T—— copper thickness The impedance becomes smaller as the copper thickness increases;

H1—Green oil thickness The resistance becomes smaller as the thickness increases;

Er—–dielectric constant The DK value of the reference layer increases, and the impedance decreases;

Undercut—-W1-W The undercut increases. The impedance becomes larger.

Impedance Calculation Automation

Today, the most commonly used impedance calculation tool in our industry is the Si8000 Field Solver provided by Polar Corporation. Si8000 is a new boundary element method field effect solution calculator software built on the easy-to-use user interface we are familiar with from earlier Polar impedance design systems. This software includes various impedance modules. It can calculate the impedance result by selecting a specific module and inputting relevant data such as line width, spacing, interlayer thickness, copper thickness, and Er value. The number of impedance control on a PCB can be as few as 4 or 5 groups or as many as dozens of groups. Each group’s control line width, interlayer thickness, copper thickness, etc., are different. If you check the data one by one and then manually enter the relevant parameters to calculate, Very time-consuming and error-prone.

The competition in PCB is getting more fierce, the sample delivery time is getting shorter and shorter, and the impedance design accounts for a large proportion of the pre-production work. A question to consider. The emergence of InPlan and InCoupon provides good help for impedance design. Of course, each PCB board factory has its impedance calculation rules, layout methods, and sizes. However, it is believed that the automation of impedance design will become more and more popular in the front of PCB manufacturing.