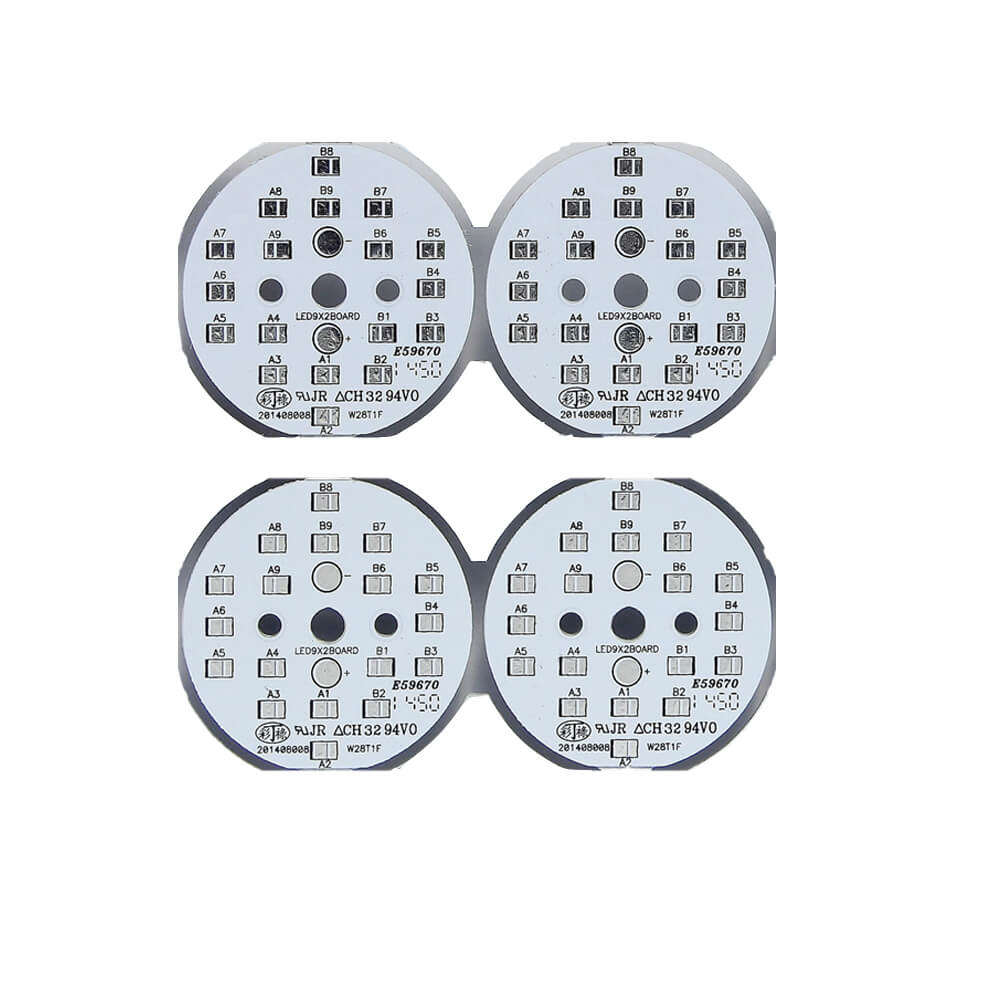

Aluminum PCB

Shipping Way

Economy Express, Standard Express, Priority Express

Cost: Factory price

Leading Time:5-30 days

Production requirements: According to documents

Standard: International standards

Custom: Yes

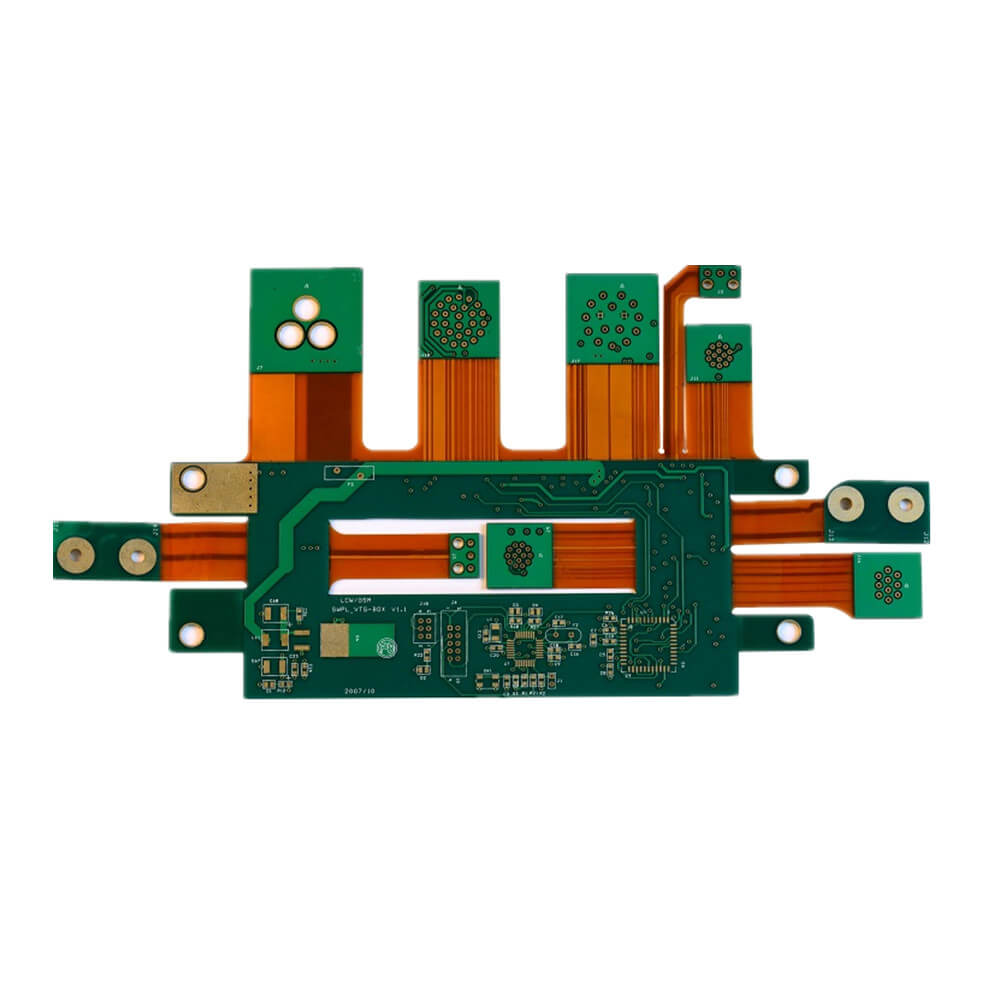

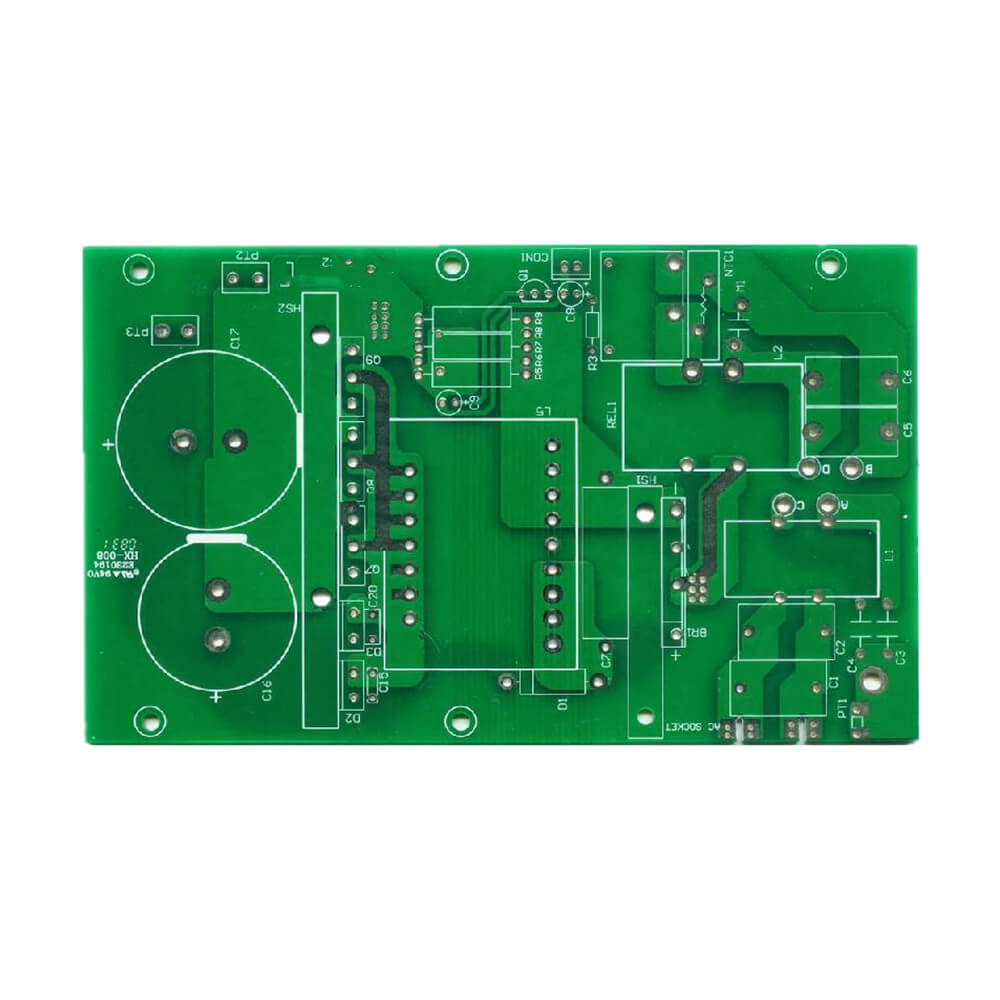

Introduction

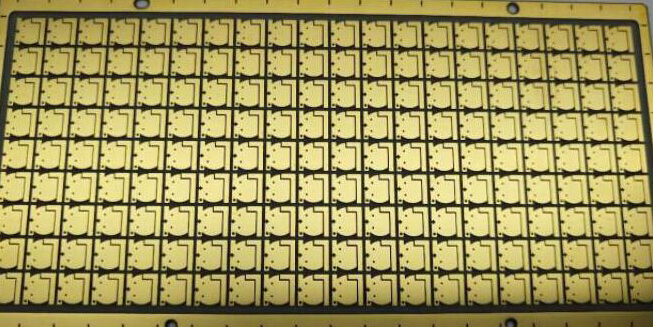

Aluminum PCB is a metal-based copper clad laminate with good heat dissipation function. Generally a single panel is composed of a three-layer structure, which is a circuit layer (copper foil), an insulating layer and a metal base layer. For high-end use, there are also designed as double-sided boards. The structure is circuit layer, insulating layer, aluminum base, insulating layer and circuit layer. Very few applications are multi-layer aluminum PCB.

Structure

Circuit Layer

The circuit layer (usually electrolytic copper foil) is etched to form a printed circuit, which is used to realize the assembly and connection of the device. Compared with the traditional FR-4, with the same thickness and line width, the aluminum PCB can carry higher current.

Insulation Layer

The insulating layer is the core technology of the aluminum PCB. It mainly plays the role of bonding, insulation and heat conduction. The insulating layer of the aluminum board is the largest thermal barrier in the power module structure. The better the thermal conductivity of the insulating layer, the more conducive to the diffusion of heat generated during the operation of the device. And the more conducive to reducing the operating temperature of the device. That achieves the purpose of increasing the power load of the module, reducing the volume, extending the life and improving the power output.

Metal Base

What kind of metal is used for the insulated metal substrate? It depends on the comprehensive consideration of the thermal expansion coefficient, thermal conductivity, strength, hardness, weight, surface condition and cost.

Under normal circumstances, considering the cost and technical performance, aluminum plate is an ideal choice. Available aluminum plates are 6061, 5052, 1060, etc. If there are higher thermal conductivity, mechanical properties, electrical properties and other special performance requirements. The copper plates, stainless steel plates, iron plates and silicon steel plates can also be used.

Features

- Using surface mount technology (SMT);

- Extremely effective treatment of thermal diffusion in the circuit design scheme;

- Reduce product operating temperature, improve product power density and reliability, and extend product service life;

- Reduce product volume, reduce hardware and assembly costs;

- Replace fragile ceramic substrates to obtain better mechanical durability

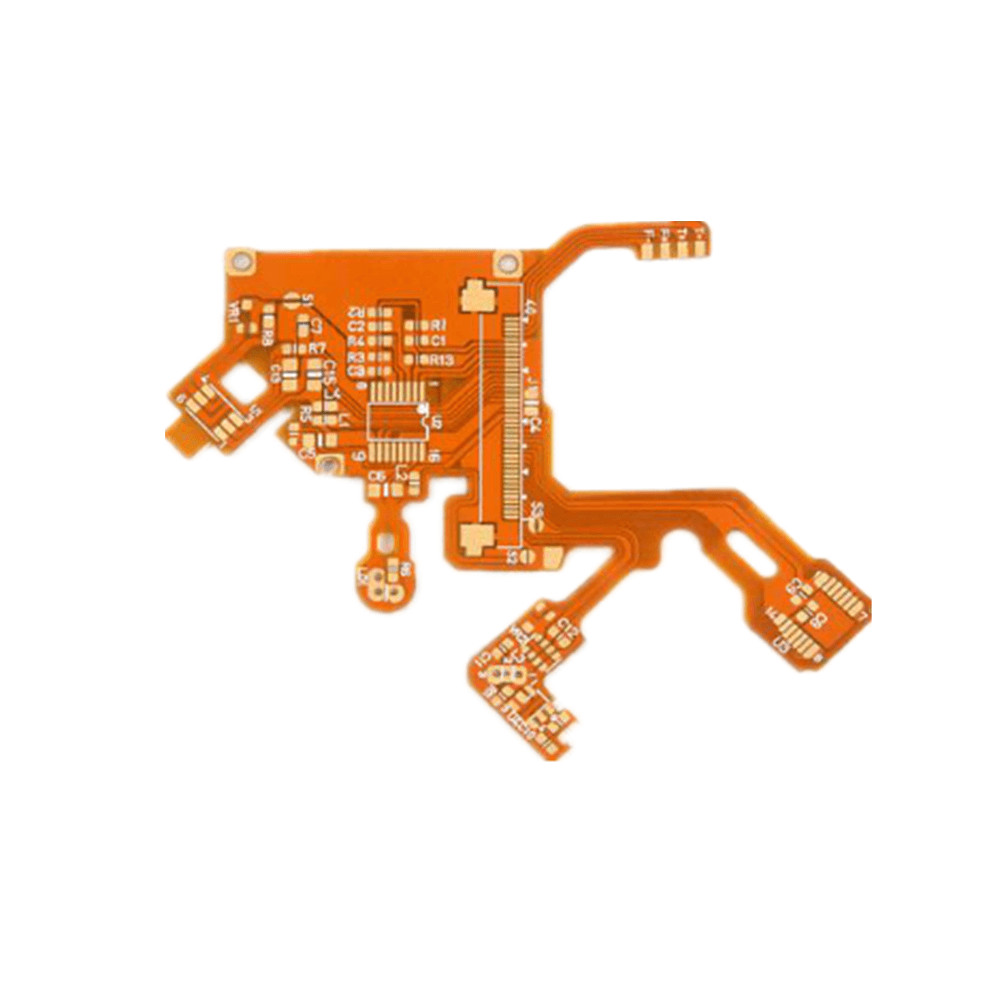

Improper operation of the assembly and connection personnel can easily cause damage to the flexible circuit. Its soldering and rework require trained personnel to operate.

Applications

- Audio equipment: input and output amplifiers, balanced amplifiers, audio amplifiers, pre-amplifiers, power amplifiers, etc.

- Power supply equipment: switching regulator, DC/AC converter, SW regulator, etc.

- Communication electronic equipment: high-frequency amplifier, filtering appliance, transmission circuit.

- Office automation equipment: motor drives, etc.

- Automobile: electronic regulator, igniter, power controller, etc.

- Computer: CPU board, floppy disk drive, power supply, etc.

- Power module: converter, solid relay, rectifier bridge, etc.

- Lamps and lanterns

Why Choose Us?

- Competitive Price

- Quality Warranty

- Excellent Service

- 24 Hours Fast Production

- 99.9% On-time Delivery

- Manufactured in China

Custom Service

Contact Us Now

Related Products

Production Process & Blog

Ceramic PCB Board Customization

Ordinary PCB is usually made of copper foil and substrate,...

Read MorePCB No-clean Process

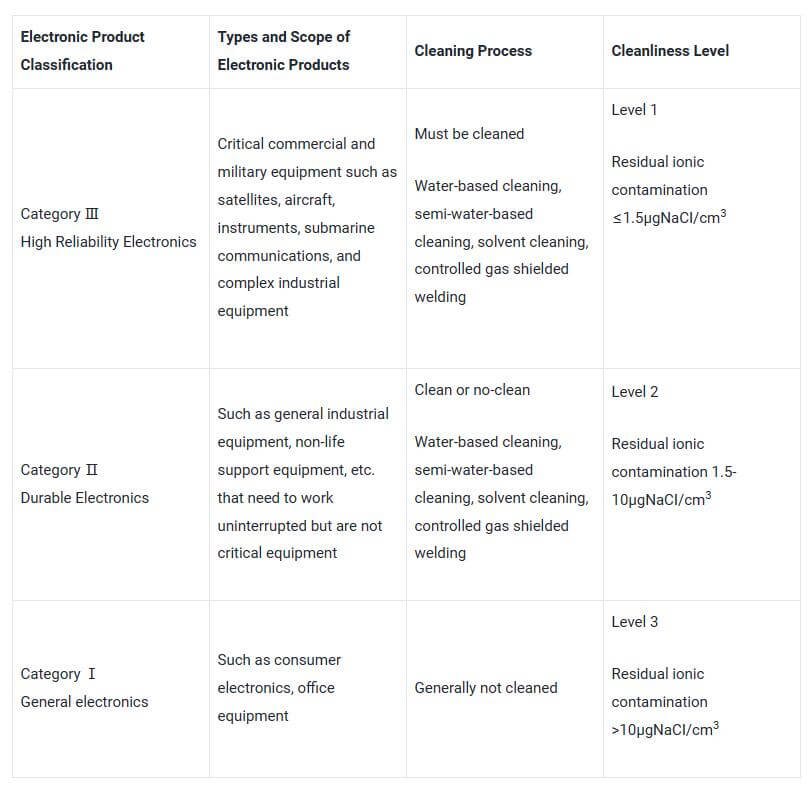

The currently available PCB cleaning processes include water-based cleaning, semi-aqueous...

Read MorePCB Cleaning And Solvent Cleaning Process

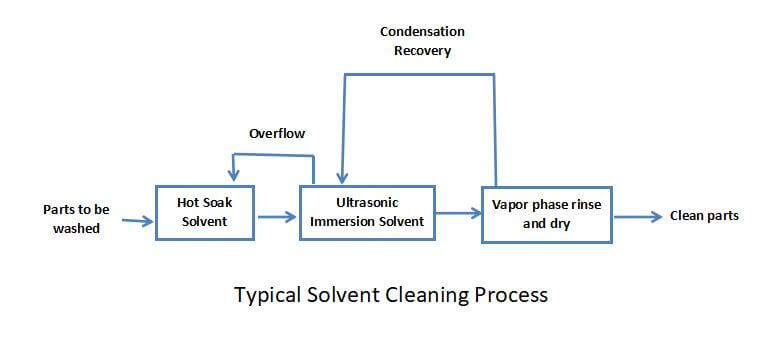

Soldering is an important step in the production of electronic...

Read More