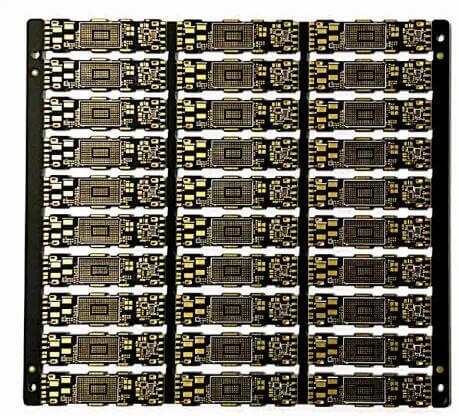

Soldering is an important step in the production of electronic equipment. After soldering, there are always varying degrees of flux residues and other types of contaminants on the circuit board surface, even if a low-solid content, halogen-free, no-clean flux is used. There will still be more or less residue. In order to prevent circuit failure due to corrosion, cleaning must be performed after welding to ensure the reliability, electrical indicators, and working life of electronic equipment. Since military products must be cleaned, the cleaning process is particularly important for military products.

The Importance of Printed Circuit Board Assembly Cleaning

- Remove flux residue, tape or solder mask residue, dust, grease, particles and sweat, and other pollutants to prevent corrosion and other defects on components, printed wires, and solder joints, and improve the quality of components’ performance and reliability;

- Remove the corrosion hazards and ensure the smooth progress of component electrical performance testing. Excessive flux residue on solder joints will prevent the test probe from making good contact with the solder joints, thus affecting the accuracy of the test results;

- Contaminants on the component surface will hinder the adhesion of the coating layer;

- The component’s appearance is clear, and defects such as thermal damage and spalling are revealed for detection and troubleshooting.

Types and Sources of Pollutants

Pollutants on the surface of printed circuit components come from a wide range of sources, mainly including pollution formed during PCB production, storage and transportation, component production, storage and transportation, and component assembly. For printed circuit assemblies, the so-called contaminants refer to surface deposits and particles that adversely affect the physical, chemical, and electrical properties of components or components. Contaminants on the surface of components are generally divided into polar or ionic contaminants, non-polar or non-ionic contaminants, and particulate contaminants.

PCB Cleaning

The traditional method of cleaning printed circuit boards is to use organic solvents. A mixed organic solvent composed of CFC-113 and a small amount of ethanol (or isopropyl alcohol) has a good cleaning ability for the residue of rosin flux, but due to the CFC-113 113 has a destructive effect on the atmospheric ozone layer and has been banned from use. The currently available non-ODS cleaning processes include water-based cleaning, semi-aqueous cleaning, and solvent cleaning. In addition, no-cleaning processes without cleaning can also be used. Today we will introduce the solvent cleaning.

PCB Solvent Cleaning Process

Organic Solvents Used to Clean Printed Circuit Boards

Using organic solvents to clean printed circuit boards takes advantage of their ability to dissolve dirt. After eliminating ODS cleaning agents such as CFC-113 and TCA, the currently used solvent cleaning agents are mainly fluorine-based solvents such as HCFC, HFC, HFE, etc. Hydrocarbon solvents, alcohol solvents, etc. can also be used. In order to improve the cleaning effect of fluorine-based solvents, hydrocarbon solvents, alcohol solvents, etc. are added to form mixed solvents. Some mixed solvents are also azeotropic mixtures with constant boiling points (such as HCFC-141b-141b and methanol, HCFC-225, and Azeotropic mixture solvent cleaning agent made of ethanol). Since these fluorine-based solvents also have the advantage of being non-flammable, and their performance is very similar to CFC-113, the cleaning process and cleaning equipment basically do not need to be changed or only need to be slightly adjusted.

Advantages of Solvent Cleaning

- The solvent cleaning process is relatively simple, use the same solvent cleaning agent for cleaning and rinsing.

- Since most solvent cleaning agents are very volatile, no special drying process is required.

- After use, the solvent can be separated from dirt through distillation and recycled, reducing costs and making waste liquid treatment relatively simple.

- Cleaning equipment originally used for CFC-113 cleaning can be used without major modification.

- Solvent cleaning is especially suitable for cleaning printed circuit boards that are sensitive to water and have poor sealing of components.

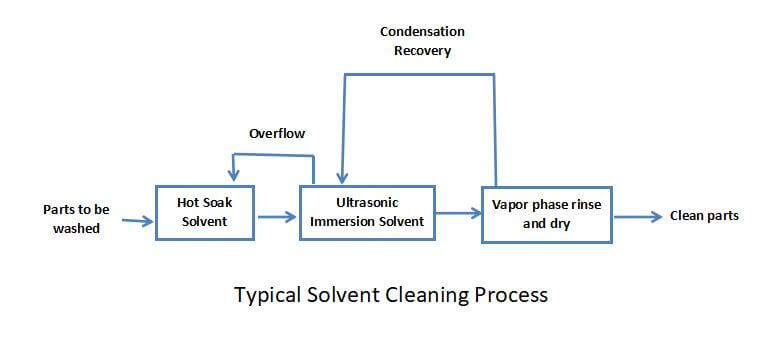

Typical Solvent Cleaning Process

Typical solvent cleaning processes include the following: ultrasonic plus immersion cleaning – spray cleaning – gas phase rinsing and dry solvent heating immersion cleaning – cold rinsing – spray cleaning – gas phase rinsing and dry gas phase cleaning – ultrasonic cleaning Soak cleaning – cold rinsing – vapor phase rinsing and drying vapor phase cleaning – spray cleaning – vapor phase rinsing and drying. See below.