The standard thickness of a printed circuit board (PCB) can vary based on the specific application, type of PCB, and the industry standards followed. However, some common standard thicknesses exist.

Here are a few examples:

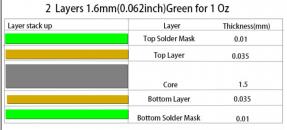

- Standard Thickness for Single-Sided PCBs: 1.6 mm (0.063 inches) is a commonly used standard thickness for single-sided PCBs.

- Standard Thickness for Double-Sided PCBs: 1.6 mm (0.063 inches) is also widely used.

- Standard Thickness for Multilayer PCBs: The thickness of multilayer PCBs can vary depending on the number of layers and the application’s specific requirements. Common thicknesses include 1.6 mm, 2.0 mm, and 2.4 mm.

It’s important to note that these are general standards, and actual PCB thickness can vary based on the specific requirements of a project. Thinner or thicker boards may be used in certain applications based on space constraints, mechanical considerations, and electrical performance requirements.

Key Factors Impact PCB Thickness

The thickness of a printed circuit board (PCB) is determined by various factors, and the choice of thickness is influenced by the specific requirements of the application. Here are some key factors that contribute to determining the thickness of a PCB.

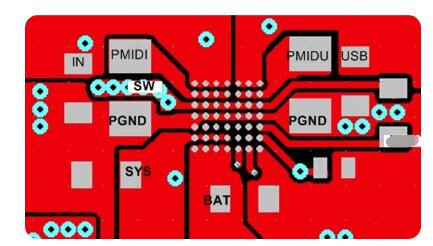

Board Material

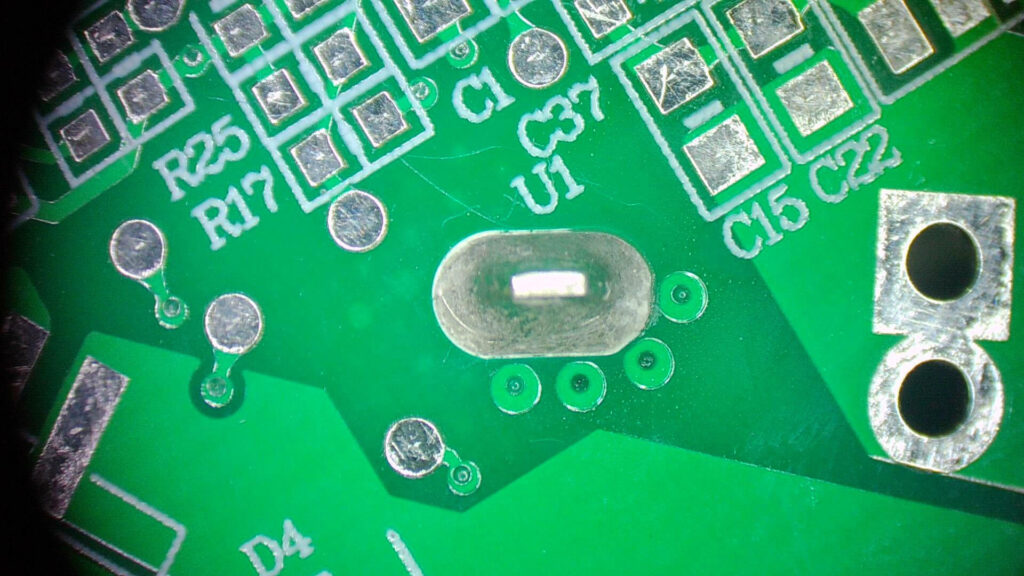

The material selection is one of the factors that decide the PCB thickness. Typically, the board fabrication materials include a substrate, laminate, solder mask, and silkscreen. Of these, the substrate and laminate material play important roles in deciding the PCB thickness, as these materials form the board’s structure. Usually, the substrate material is epoxy resin, glass weave, or ceramic, and the laminate material is thermoset resin and either paper or cloth layers. These materials not only decide the PCB thickness; they also decide the thermal, mechanical, and electrical properties of the circuit board.

- Thermal Considerations

Thicker PCBs can have better heat dissipation properties. A thicker PCB may be chosen to help dissipate heat more effectively in applications where thermal management is crucial. - Mechanical Strength

The mechanical strength of the PCB is an important consideration. The thickness is chosen to ensure that the PCB can withstand mechanical stress during handling, assembly, or in the intended operating environment. - Electrical Performance

The electrical characteristics of the PCB, such as impedance control and signal integrity, can be influenced by its thickness. Some applications may require a specific thickness to meet performance requirements.

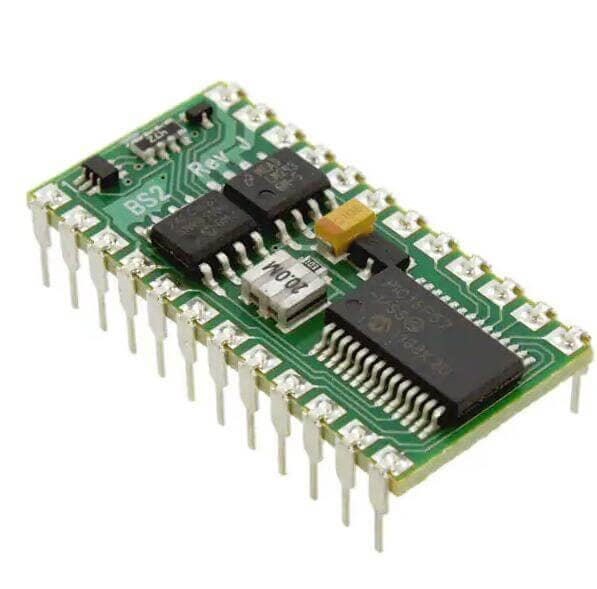

Layer Count

The number of PCB layers is a major factor that decides the PCB thickness. Based on the application requirement, the number of PCB layers can vary. The higher the number of layers, the thicker the board. A standard PCB with a thickness of 1.57 mm (0.062 inch) can have 2 to 6 layers. Anything more than this would result in a thicker printed circuit board. The layer count can be up to 60 layers in some cases, so the board thickness can increase significantly. The manufacturing of multi-layer boards becomes significantly more challenging.

Copper Thickness

The thickness of the copper layers on the PCB (copper weight) is a factor. When a PCB uses a thicker copper layer the etching process becomes more complicated and can result in the board becoming more expensive to fabricate. Heavier copper layers may require a thicker substrate to maintain mechanical stability and prevent warping.

Space Constraints

The available space within the device or system can be a limiting factor. Thinner PCBs might be preferred in compact electronic devices to save space and reduce weight.

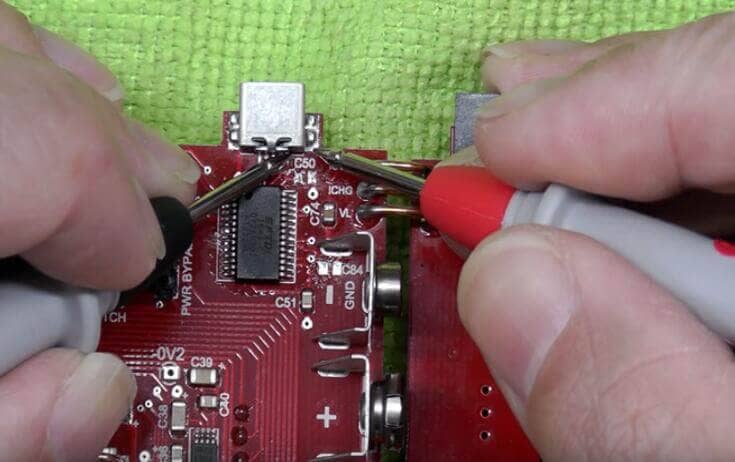

Assembly Process

The chosen thickness should be compatible with the assembly processes, including component placement and soldering techniques. Thicker boards may require adjustments in assembly processes.

Cost Considerations

The cost of materials and manufacturing processes may influence the chosen thickness. Thicker boards often involve more material and may have higher manufacturing costs.

Industry Standards and Regulations

Certain industries or applications may have standards and regulations that dictate the acceptable thickness for PCBs. Compliance with these standards is essential, especially in safety-critical or regulated environments.

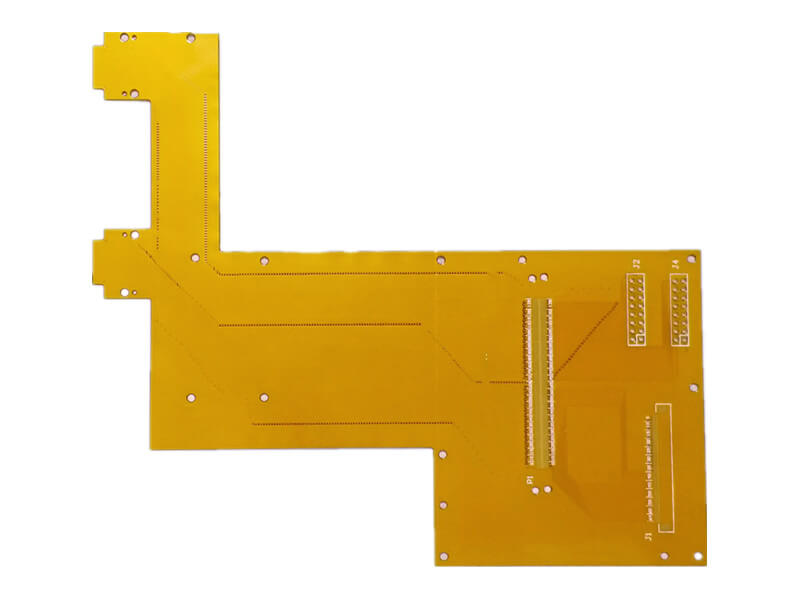

Size, Weight, and Flexibility

Selecting the right PCB thickness for your application depends on several factors. A rigid thin PCB board is usually brittle and can break or crack easily. So, this would not be the right board for use in a rugged environment. A thicker rigid board will be more durable. However, in certain cases, flexible boards are required, the thinner the board the more flexible it is. So this is very subjective and depends on the customer’s application.

When designing a PCB, engineers consider these factors collectively to determine the most suitable thickness for the specific application’s needs. It’s common for PCB manufacturers to offer a range of standard thickness options to accommodate various requirements.