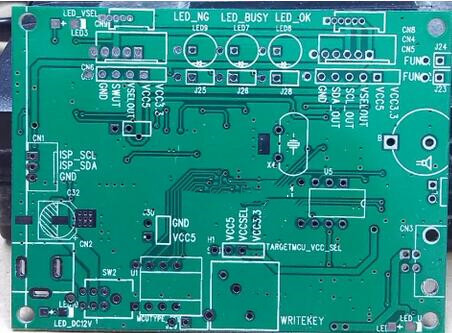

In the manufacturing process of the circuit board, the following two methods are usually used to solder the pins of the components to the circuit board: one is to directly solder each pin to the circuit board; the other is to paint the solder paste on the pins. Put the components and the circuit board into a high-temperature oven to bake to melt the solder paste, and then solder after the solder paste solidifies. The disadvantage of the first method is that when the number of pins is large and the pin density is high, it is difficult to weld one by one, and it is difficult for personnel to operate, thereby affecting the welding effect. The defect of the second method is that the baking temperature in the oven is relatively high, usually up to 300 or 400 degrees Celsius, which will cause abnormalities in the parts that are not resistant to high temperatures in the components or circuit boards and affect the product quality. If the parts that are not resistant to high temperatures are replaced The use of high-temperature resistant materials will greatly increase the cost of the product.

In order to overcome the defects of circuit board component pin welding, we introduce an automatic laser welding method that is easy to operate, does not cause product quality problems, and is low in cost.

Laser solder paste automatic welding

Step 1: Place the product on the feeding tray (the specification of the tray is customized according to the size and efficiency requirements of the product, and each tray can hold multiple products, or provided by the customer.), and then place the component pins on the position to be welded on the circuit board is fixed with a special welding fixture, and then the plate with the material is placed on the jig on the right side of the machine. Start the button to start feeding.

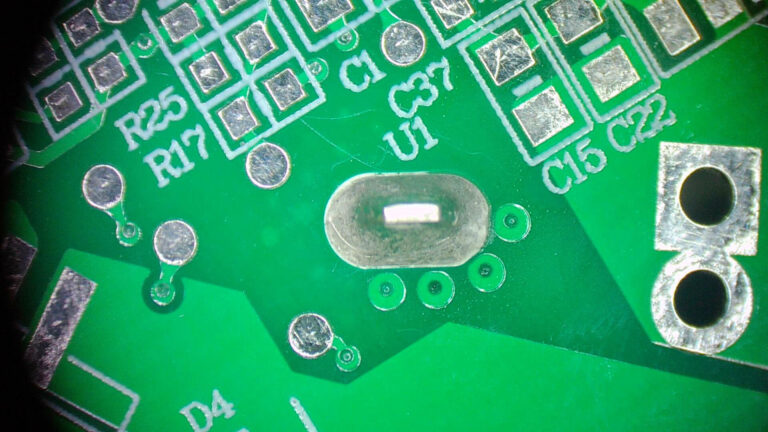

Step 2: Servo move the circuit board and component pins to the visual starting point, and the height measurement system and the CCD visual positioning system will custom capture the welding position and take pictures until all the products on the tray are photographed, and then enter the next step At the solder paste station, draw a strip of solder paste on the pin along the direction perpendicular to the pin arrangement direction of the component.

Step 3: Servo-moving the reel with solder paste strips to the laser welding station, the high-energy continuous laser melts the solder paste so that the component pins are welded to the circuit board until all the products on the reel are completely welded, move to the blanking station for blanking.

Laser tin wire automatic welding

Step 1: Same as the solder paste soldering steps above, with manual and automatic feeding;

Step 2: It is basically the same as the above solder paste soldering steps, the only difference is: tinning and soldering are basically completed at the same time.

Step 3: Move the product on the tray to the tin welding station. The amount of tin output can be controlled according to the software program. The tin wire is melted by the laser. The melted tin wire makes the component pins welded to the circuit board and finally moves to the manual unloading station for unloading.