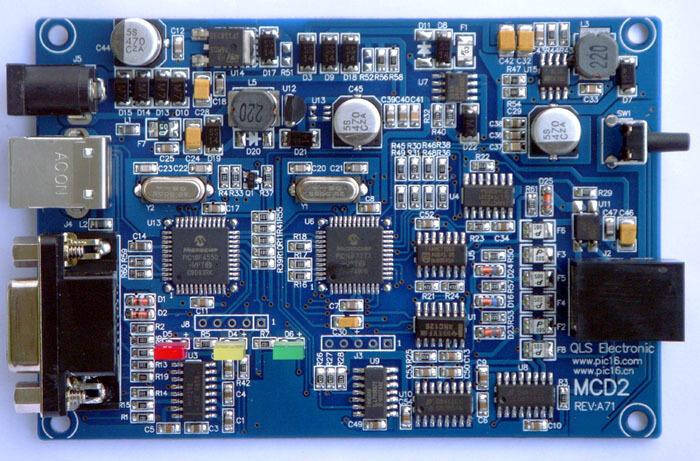

PCB prototyping refers to the production of a small number of sample PCB boards before formal mass production to verify the correctness of the circuit design, the rationality of the PCB layout, the reliability of the materials, and the feasibility of the process, etc., to modify or optimize the PCB board. Improve the quality and performance of PCB boards, and reduce the risk and cost of subsequent production.

The following preparations need to be done before PCB prototyping

- Determine the quantity and size of the proofing PCB board. According to the actual demand, determine the quantity and size of the PCB boards that need to be produced, to carry out subsequent material procurement and production planning.

- Confirm the accuracy of circuit design and PCB layout. Ensure the circuit design and PCB layout accuracy, and avoid production failures and delays caused by design and layout problems.

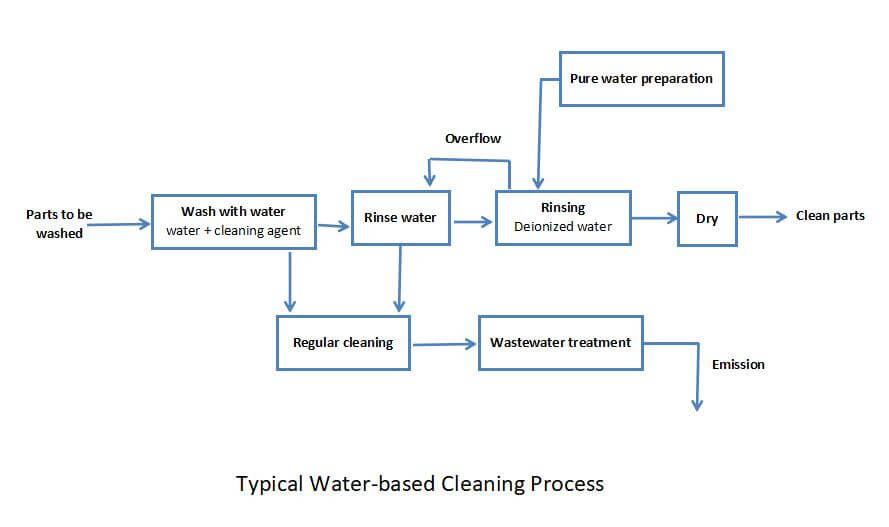

- Determine the material and process of the PCB board. According to the actual needs and design requirements, determine the material and process of the PCB board, including the substrate type of the PCB board, copper foil thickness, coating material, printing ink, etc.

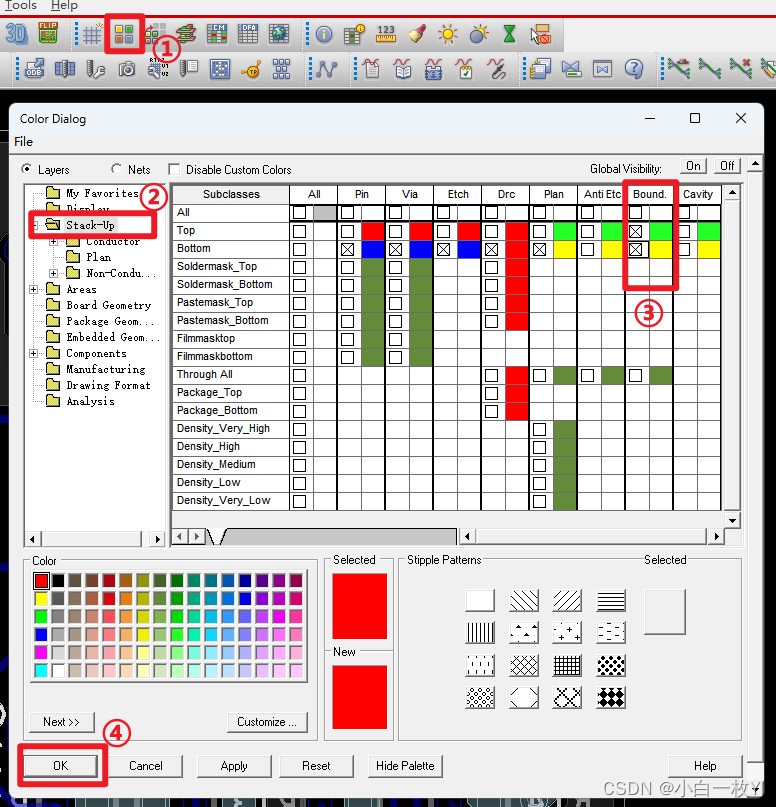

- Prepare PCB production drawings and fabrication process documents. Before making PCB prototyping, it is necessary to prepare PCB production drawings and manufacturing process documents, including PCB board layout drawings, drilling drawings, cutting drawings, copper cladding drawings, printing ink drawings, AOI drawings, etc.

- Choose the right PCB manufacturer. According to the quantity and requirements of PCB boards, select the appropriate PCB manufacturer for production, including the consideration of the PCB manufacturer’s production capacity, quality control, delivery cycle, after-sales service, etc.

In short, PCB prototyping is an important production process, which requires adequate preparation to ensure that the quality and performance of the PCB board meet the requirements and reduce subsequent production costs and risks.