printed circuit boards Introduction

What's PCB?

PCB is a printed circuit board and one of the important parts of the electronics industry. Almost every kind of electronic equipment(electronic watches, calculators, computers, communication electronic equipment, military weapon systems, etc.,) are all need use PCB. It can make the electrical interconnection between the various components. And now printed circuit boards have been extremely widely used in the manufacture of electronic products.

Features

- High-Density

Over the years, the high density of printed boards has been able to develop correspondingly with the improvement of integrated circuit integration and the advancement of mounting technology. - High Reliability

Through a series of inspections, tests and aging tests and other technical means, the PCB can be guaranteed to work reliably for a long time (usually 20 years). - Design-ability

The requirements for various properties of PCB (electrical, physical, chemical, mechanical, etc.) can be achieved through design standardization and standardization. In this way, the design time is short and the efficiency is high. - Manufacture-ability

PCB adopts modern management, which can realize standardization, scale (quantity) and automatic production. So as to ensure the consistency of product quality. - Test-ability

A relatively complete test method and test standard have been established. Various test equipment and instruments can be used to detect and appraise the eligibility and service life of PCB products. - Assembly-ability

PCB products are not only convenient for standardized assembly of various components, but also for automated and large-scale mass production. - Maintainability

Since PCB products and various components are assembled in a standardized design and large-scale production, these components are also standardized. Therefore, once the system fails, it can be replaced quickly, conveniently and flexibly. And the system can be quickly restored to work.

PCB has other advantages, such as miniaturization and light weight of the system and high-speed signal transmission.

Functions in Electronic Equipment

- PCB provides mechanical support for the fixing and assembly of various electronic components. Such as integrated circuits, realize the wiring and electrical connection. It also make electrical insulation between various electronic components such as integrated circuits. And it provides the required electrical characteristics.

- PCB provide solder mask graphics for automatic welding. It provides identification characters and graphics for component insertion, inspection and maintenance.

- After electronic equipment adopts printed boards, manual wiring errors can be avoided because of the consistency of similar printed boards. Electronic components can be automatically inserted or mounted, automatic soldering and detection. It ensures the quality of electronic products and improves labor productivity, reduces costs and facilitates maintenance.

- PCB provides required electrical characteristics, characteristic impedance and electromagnetic compatibility characteristics for circuits in high-speed or high-frequency circuits.

- The printed circuit board with passive components embedded inside provides certain electrical functions. It simplifies the electronic installation procedure and improves the reliability of the product.

- In large-scale and ultra-large-scale electronic packaging components, PCB provides an effective chip carrier for the miniaturized chip packaging of electronic components.

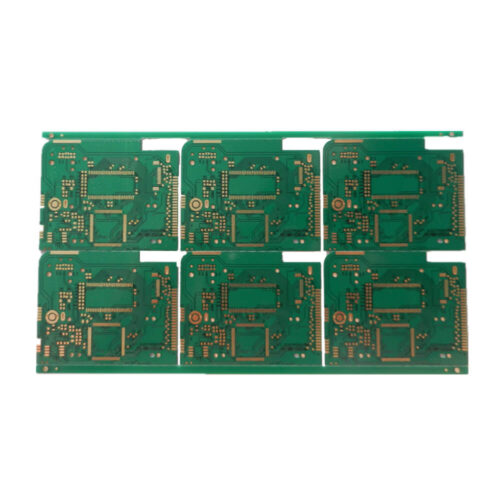

our pcb products Show

Quick Turn PCB Prototyping

Rigid, Flexible, Rigid-flex & Aluminum PCB FAB

3-4 Days or 24 Hours Urgently

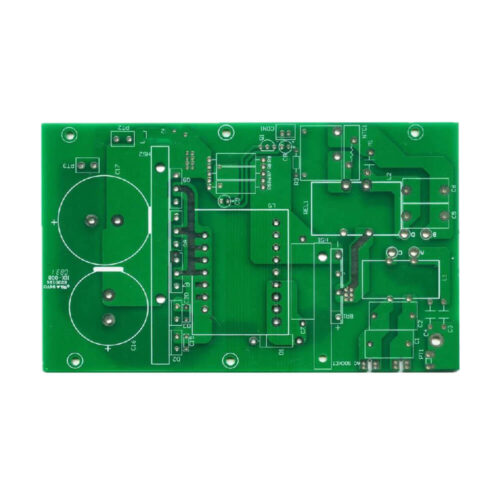

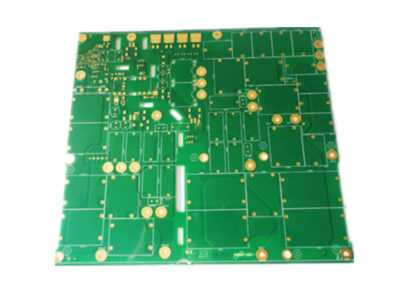

Rigid PCB Prototyping

Material: FR4

Classification: Single-sided PCB, Double-sided PCB & Multi-layer PCB

7-15 Days

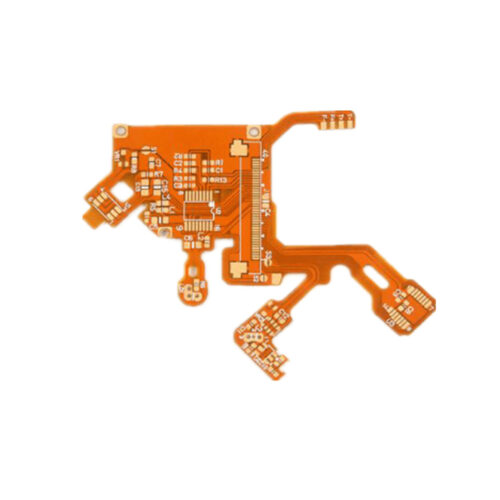

Flexible PCB Prototype

Material: Polyimide or polyester film

Features

- Light weight

- Thin thickness

- Free bending and folding

7-30 Days

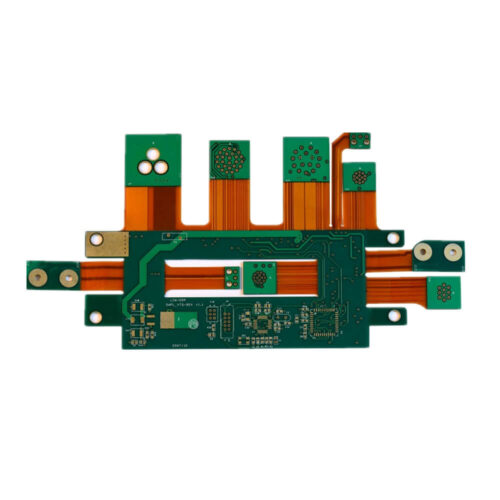

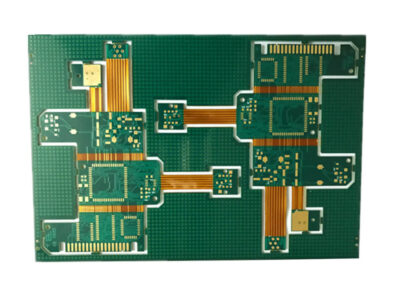

Rigid-flex Board Manufacture

The combination board of flexible circuit board and hard circuit board is a circuit board with FPC characteristics and PCB characteristics.

Applications: mobile phone, key board and side keys, computer and LCD screen, mainboard and display screen, CD Walkman, disk drive, notebook, etc.,

About 7-10 Days

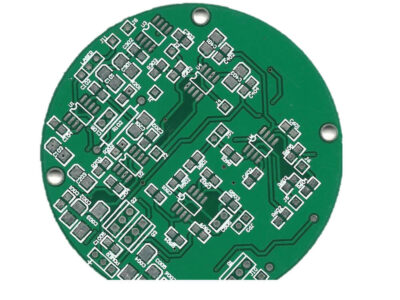

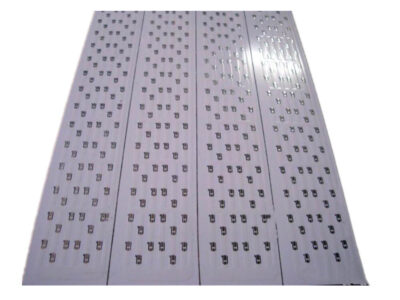

Aluminum PCB Produce

Material: Aluminum alloy

Features

- Good thermal conductivity

- Electrical insulation performance

- Machinability

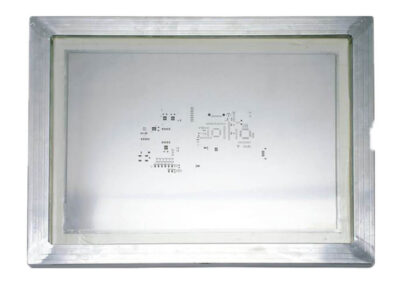

PCB & SMT Stencils FAB

Standard pcb: single-sided, double-sized, multi-layer PCB & SMT Stencil Manufacture

With & Without Frame

SMT Stencil

1 days produce time. The stencil can be with frame in standard size or without frame that the finished product with custom size.