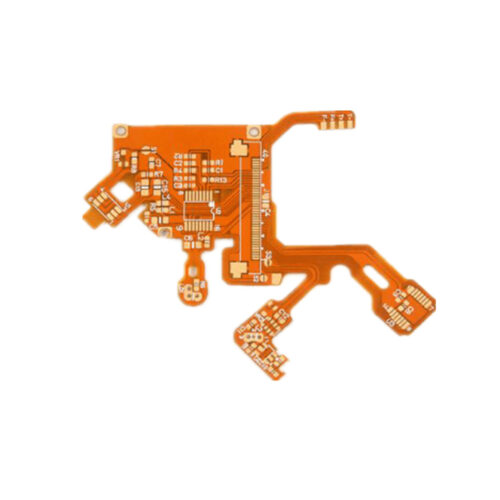

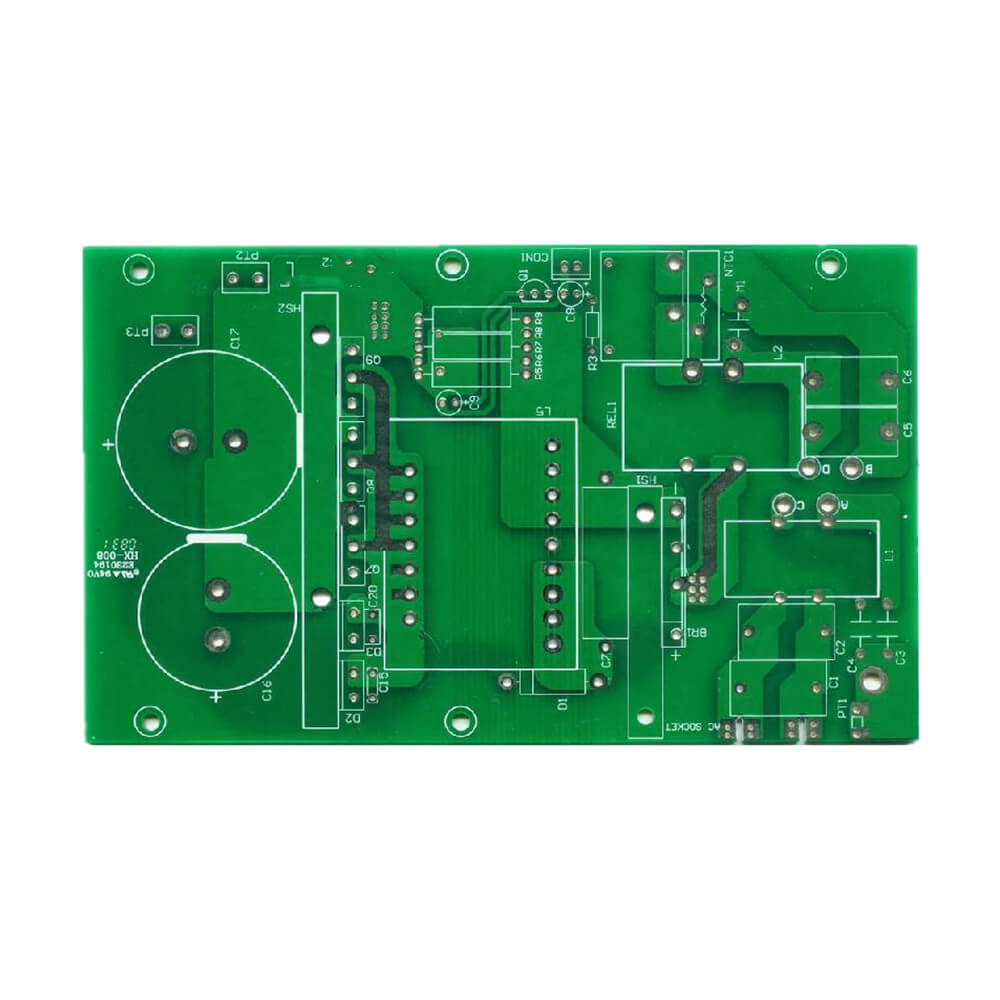

Flexible PCB

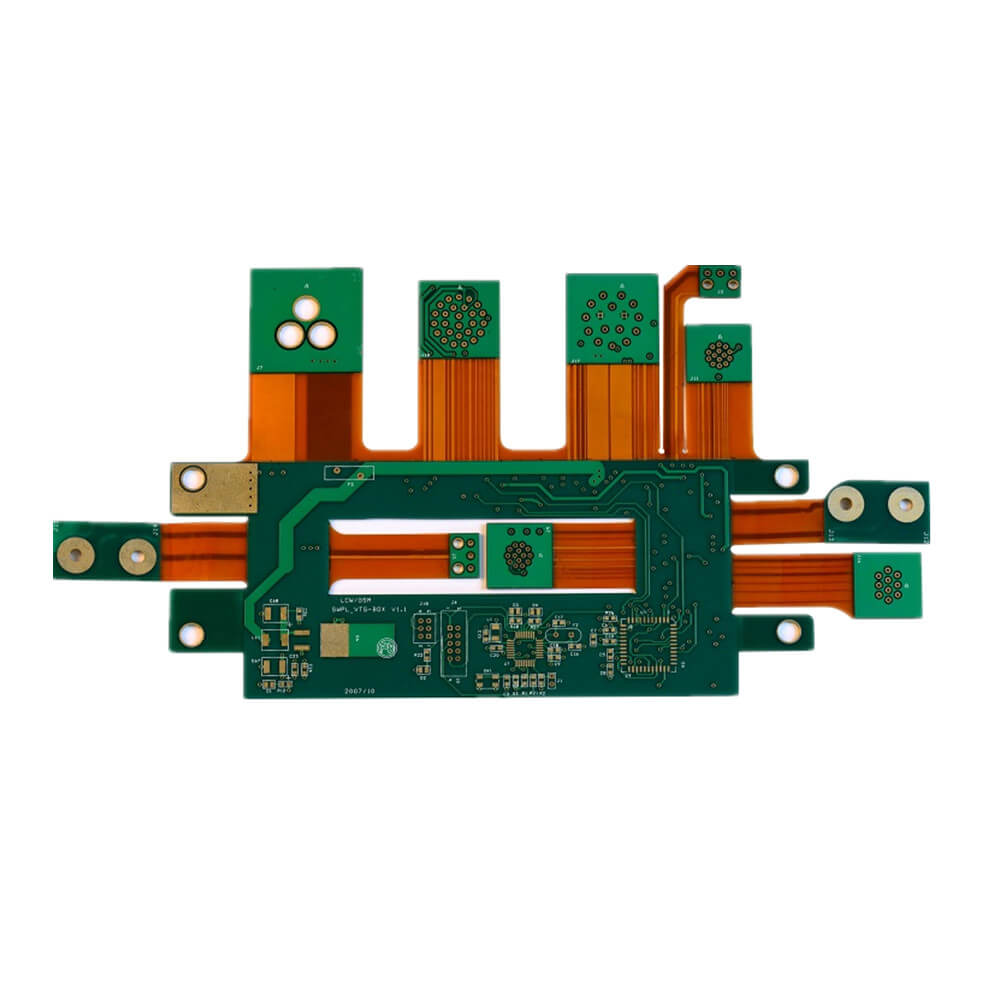

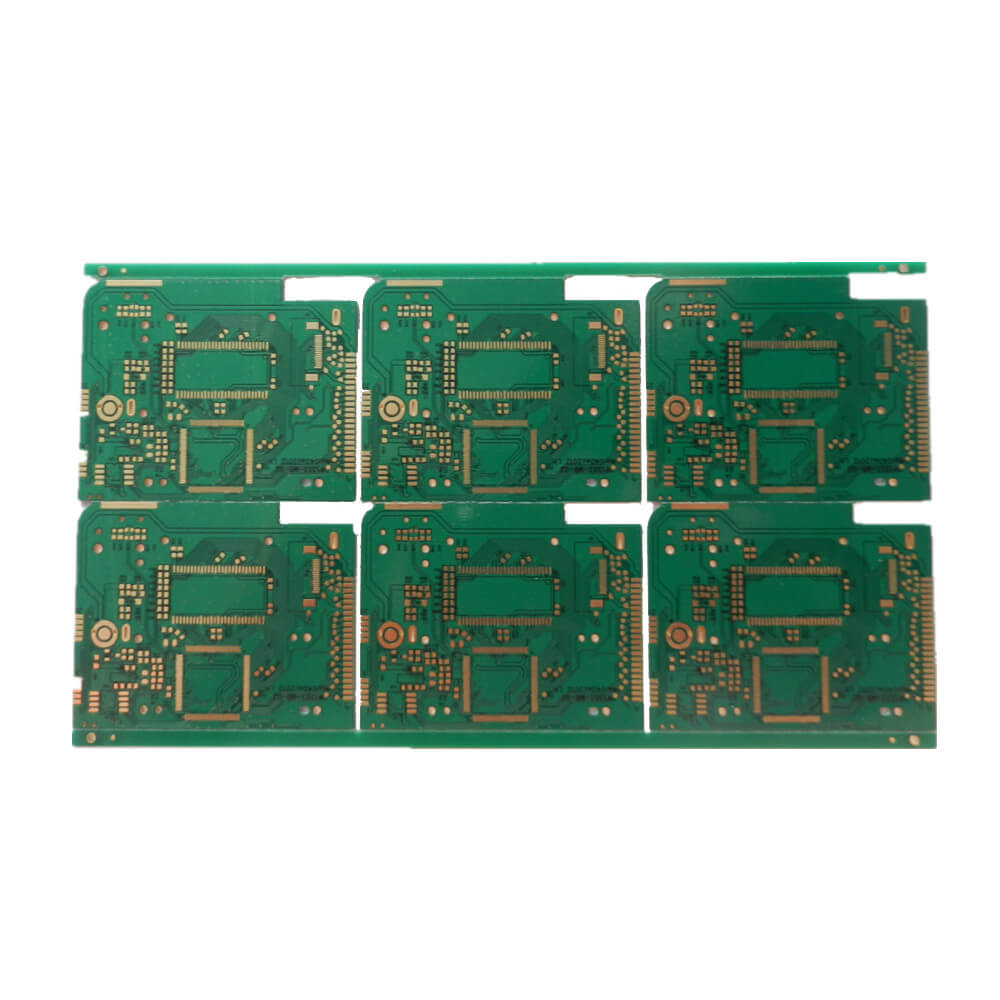

Layer: 1, 2 & mulit-layer

Shipping Way

Economy Express, Standard Express, Priority Express

Cost: Factory price

Leading Time:5-21 days

Production requirements: According to documents

Standard: International standards

Introduction

Flexible Printed Circuit Board is referred to as “soft board”. It’s commonly known as FPC in the industry. And it is made of flexible insulating substrates (mainly polyimide or polyester film).

Species

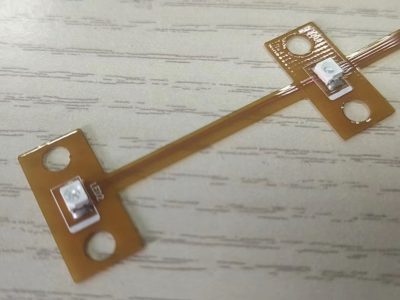

- Single Side Board

The single-sided PI copper-clad material is used after the circuit is completed. And then covered with a protective film to form a flexible circuit board with only a single-layer conductor. - Double Side Board

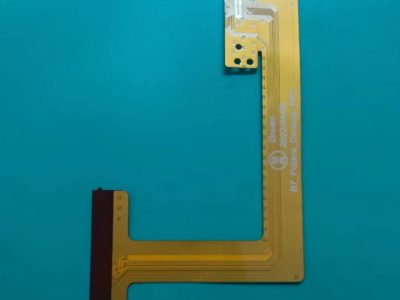

After the double-sided circuit is completed with double-sided PI board copper-clad material, a protective film is added on both sides. Then it become a circuit board with double-layer conductors. - Substrate to Generate Single Board

In the circuit manufacturing process using pure copper foil material, a protective film is added on each side of the board. Then it becomes a circuit board with only a single layer of conductors but exposed conductors on both sides of the circuit board. - The Substrate Generates Double Side Board

Use two layers of single-sided PI copper-clad material in the middle, supplemented by adhesive glue that opens at a specific position. It becomes pressed in a local area. Then it achieves a circuit board with high flexibility in the layered area.

- Single Side Board

Advantages

- FPC can be bent, wound and folded freely. It can be arranged according to the space layout requirements, moved and expanded in three-dimensional space. Then achieve the integration of component assembly and wire connection;

- The use of FPC can greatly reduce the volume and weight of electronic products;

- FPC also has the advantages of good heat dissipation and solder-ability. It’s easy assembly and connection.

Disadvantages

- High One-time Initial Cost

Since flexible PCBs are designed and manufactured for special applications, the cost of initial circuit design, wiring and photographic masters is high. Unless there is a special need to apply a flexible PCB, it is usually best not to use it for a small number of applications. - It is Difficult to Modify and Repair Flexible PCBs

Once the flexible PCB is made, it must be changed from the base map or the programmed light drawing program, so it is not easy to change. The surface is covered with a protective film, which must be removed before repair and restored after repair. This is a relatively difficult task. - Size is Restricted

When flexible PCBs are not yet popular, they are usually manufactured by batch process. They cannot be made very long and wide due to the limitation of the size of the production equipment. - Improper Operation is Easy to Damage

Improper operation of the assembly and connection personnel can easily cause damage to the flexible circuit. Its soldering and rework require trained personnel to operate.

Why Choose Us?

- Competitive Price

- Quality Warranty

- Excellent Service

- 24 Hours Fast Production

- 99.9% On-time Delivery

- Manufactured in China

Custom Service

Contact Us Now

Related Products

Production Process & Blog

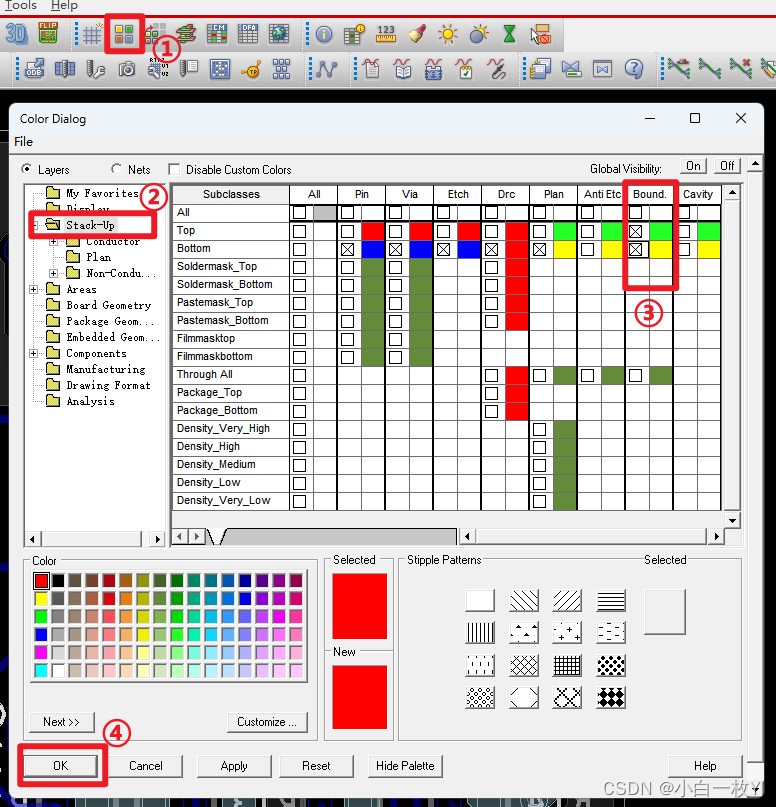

How to Restore Deleted Isolated/hollowed-out Copper?

To restore deleted isolated copper or hollowed-out copper skin in...

Read MoreBest PCB Suppliers for Small-Batch Production

Looking for reliable PCB manufacturers specializing in low-volume orders? Here...

Read MoreDry Film & Application Processes

The company uses dry film in the production process, combined...

Read More