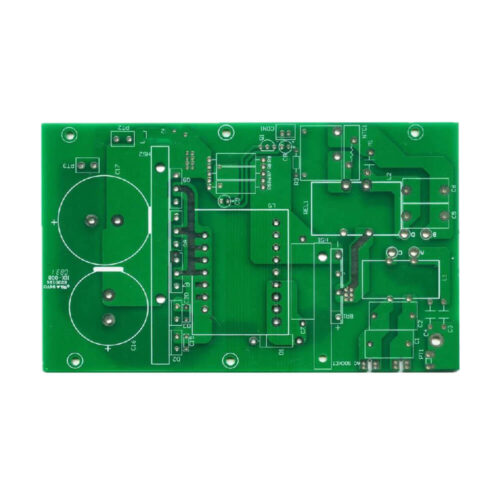

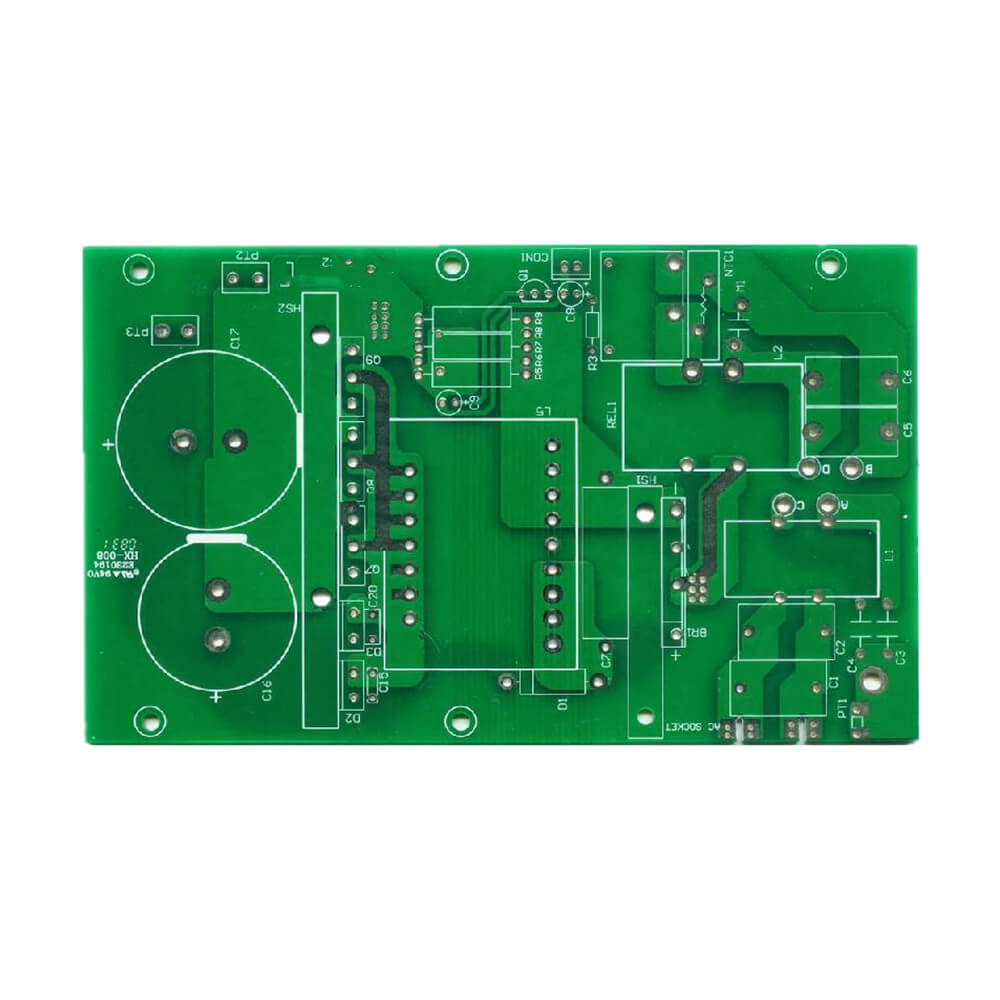

Rigid PCB Prototyping

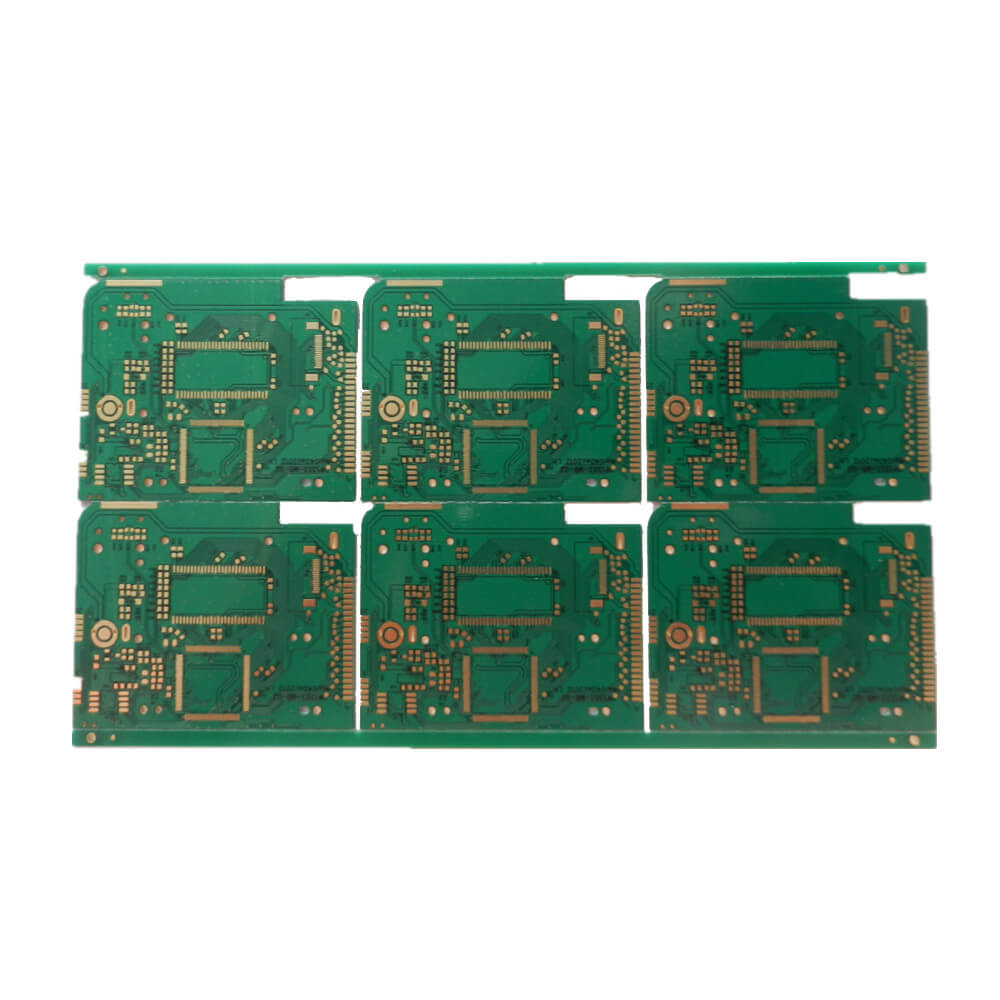

Mini QTY: 5

Layer: 1, 2 & mulit-layer

Color: White, Black, Green, Red, Yellow, Blue, Pink

Shipping Way

Economy Express, Standard Express, Priority Express

Cost: Low to $5

Leading Time

- 3-5 days for prototyping(5 pcs)

- One week for batch production(More than 50 pcs)

Rigid printed circuits boards include phenolic paper laminates, epoxy paper laminates, polyester glass mat laminates and epoxy glass cloth laminates.

FR-4 PCB

FR-4 is a code for the grade of flame resistant material, which means that the resin material must be able to extinguish itself after combustion. It is not a material name, but a material grade.

Therefore, there are many kinds of FR-4 grade materials used in general circuit boards, but most of them are composites made of so-called Tera function epoxy resin, filler and glass fiber.

Performance characteristics of FR-4

FR-4 epoxy glass fiber cloth substrate is a kind of substrate with epoxy resin as adhesive and electronic glass fiber cloth as reinforcing material. Its adhesive sheet and inner core thin copper clad laminate are important substrates for making multilayer printed circuit boards.

The mechanical properties, dimensional stability, impact resistance and moisture resistance of epoxy glass fiber cloth substrate are higher than those of paper substrate. Its electrical performance is excellent, its working temperature is high, and its performance is less affected by the environment. In the processing technology, it has great advantages over the glass fiber cloth base plate of other resins. This kind of products are mainly used for double-sided PCB, with a large amount. Epoxy glass fiber cloth substrate, the most widely used product model is FR-4.

FR-4 General Technical Indexes of Sheet Metal

- Flexural strength

- Peel strength

- Thermal shock performance

- Flame retardant performance

- Volume resistance coefficient

- Surface resistance

- Dielectric constant

- Dielectric loss tangent

- Glass transition temperature Tg

- Dimensional stability

- Maximum service temperature

- Warpage

Features

High density, high reliability, designability, manufacturability and testability.

Funcitons

Avoid manual wiring errors , automatically inserted & mounted electronic components, automatic soldering & detection, ensuring the quality of electronic equipment , improve labor productivity, reduce costs, easy to maintain, etc.,

Applications

- Industrial Controller

- Medical Equipments

- Security Products

- Consumer Electronics

- UAV Drone

- Power Electronics

Why Choose Us?

- Competitive Price

- Quality Warranty

- Excellent Service

- 24 Hours Fast Production

- 99.9% On-time Delivery

- Manufactured in China

Custom Service

PCB Price Calculation

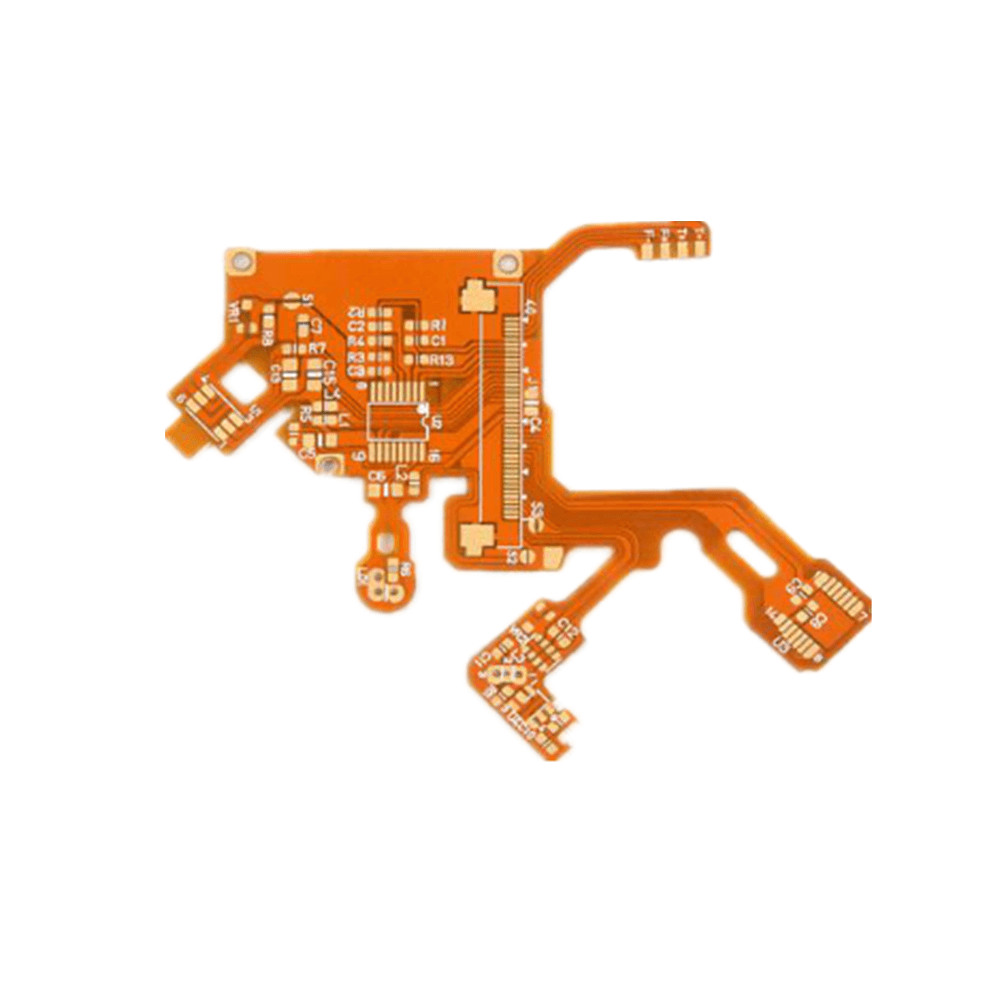

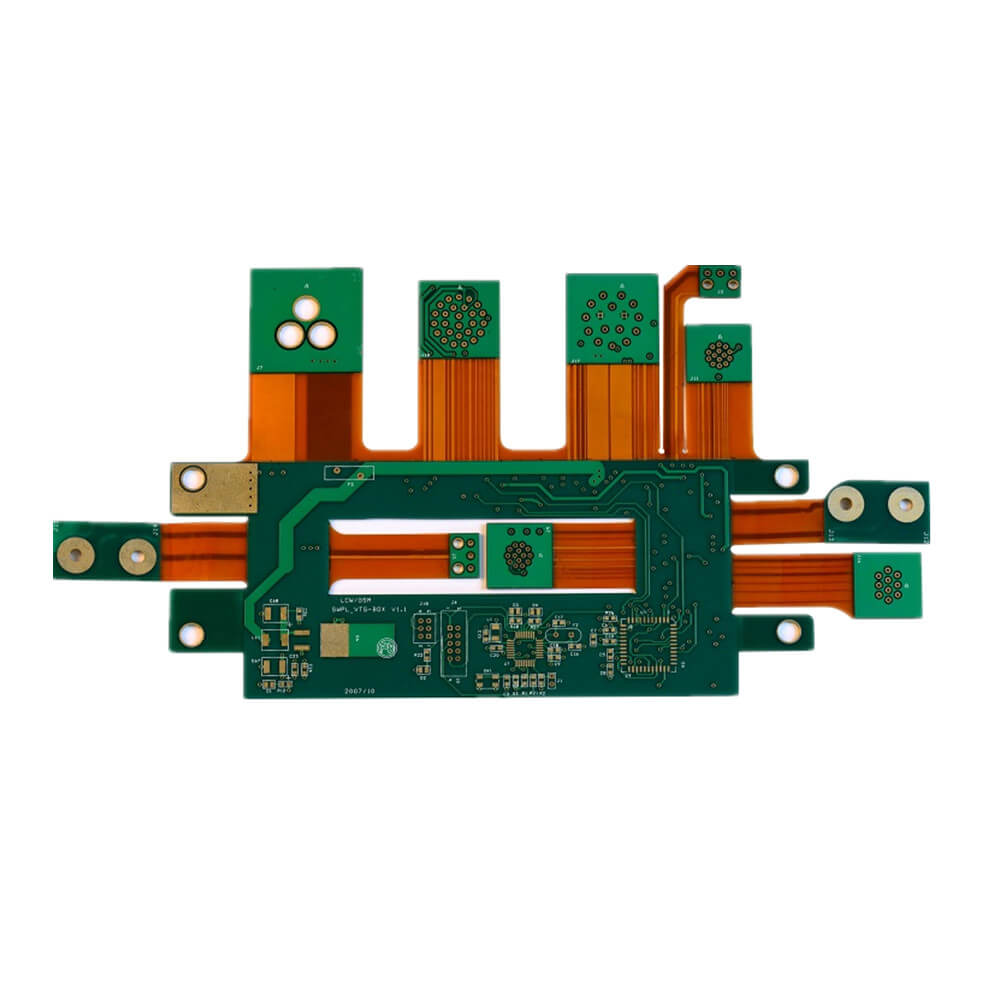

Related Products

Production Process & Blog

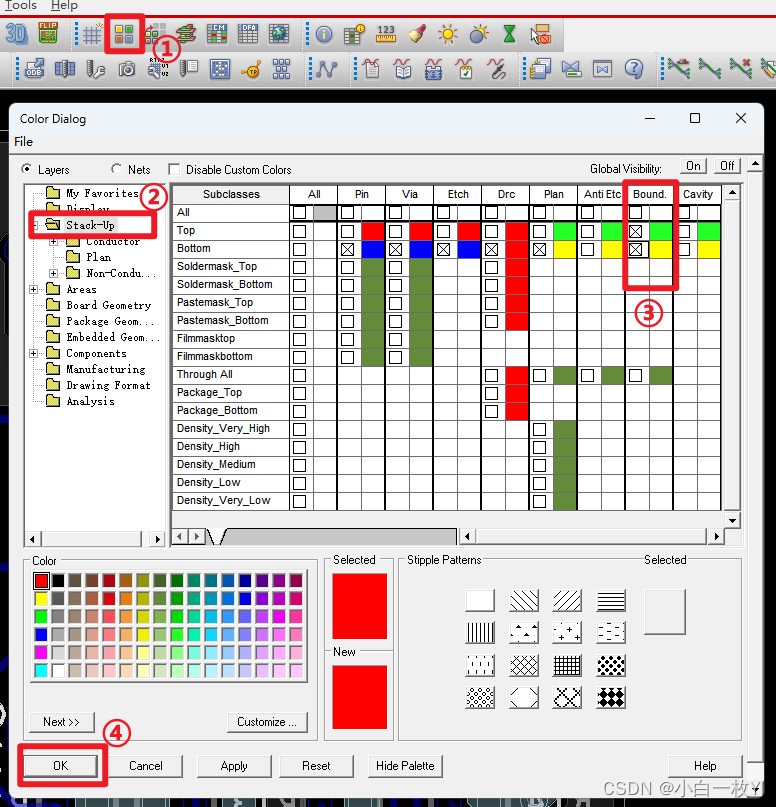

How to Restore Deleted Isolated/hollowed-out Copper?

To restore deleted isolated copper or hollowed-out copper skin in...

Read MoreBest PCB Suppliers for Small-Batch Production

Looking for reliable PCB manufacturers specializing in low-volume orders? Here...

Read MoreDry Film & Application Processes

The company uses dry film in the production process, combined...

Read More