Because most of the modern printed circuit boards have no official schematic and more and more chip applications with programs, engineers will face challenges in various aspects. Through a lot of practice, there are still ways to avoid these challenges. I will share 6 maintenance methods of PCB.

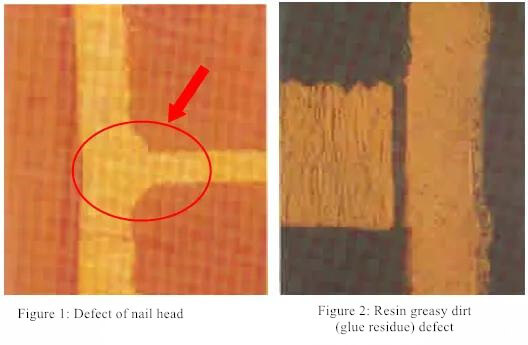

Tip 1: Appearance Inspection

Looking, asking, smelling and cutting. To observe whether there is burning place on the circuit board or not, whether copper is applied to have broken place. Smell whether there is peculiar smell on the circuit board, whether there is bad welding place, whether the interface and gold finger have mildew and blackening. Also ask the customer about the failure phenomenon and the process of the fault, the focus of the fault can be focused on some parts. Through the above treatment, we can often find some problems.

Tip 2: General Killing

All components will be tested once and the defective components shall be replaced to achieve the purpose of repair. If the components that cannot be detected by the instrument are encountered, the replacement method shall be adopted. It means whether the component is damaged or not, new component shall be used instead. So as to ensure that all the devices on the board are good and achieve the purpose of repair. The method is simple and effective, and the technical level of the engineer is not high. But the operation requires high care and responsibility. Otherwise some devices do not remember the position when they are removed. And the wrong installation will lead to failure of maintenance. In addition, the method can’t be used to solve the problems such as the hole is not available, copper deposit is broken and potentiometer is not adjusted properly. This method can’t be used when encountering chips with programs and data.

Tip 3: Comparison

The comparison method is one of the most common methods for maintenance of circuit boards without drawings. Practice proves that it has very good effect. Through the comparison with the good board state, the purpose of finding out the fault is achieved. And the abnormal is found by comparing the curves of each node of the two boards. However, many times we don’t have a good board to compare,

but this does not mean that we can not use this method. For example, we can find the circuit with the same properties in the circuit board. There are three same interfaces in a board, and the three interfaces have the same circuit, we can use the curve of three identical interfaces to compare each other to judge the problem. When we can’t find the above mentioned situation, we can still find the circuit with common properties. Such as the bus in the circuit usually has the same curve. At other times, we can’t judge whether an IC is damaged or not, and we may also use scanning curve to compare with good IC to achieve the purpose of judging. In short, we need to use our brains to bring the contrast to the extreme. Curve scanning is really useful in practice, but some beginners don’t understand its working principle and the weariness instrument has no practical value. So I have seen many companies in the same industry basically use the circuit board maintenance tester, and call it on. Of course the merchants are also suspected of exaggerating the function. In fact when scanning the integrated circuit of COMS process, the curve of each scan is different, which makes it impossible to judge. This reason is caused by the high impedance of CMOS and the failure of drain channel after charging the inter junction capacitance. Therefore it needs rich experience to judge CMOS integrated circuit. Finally it is necessary to add that curve scanning is the peripheral device of scanning. If the scan is integrated circuit, it is the components connected to the pins in the scanned IC. 90% of the IC damage is peripheral device damage. In case of non peripheral device damage, the problem can not be found in scanning curve, and the device will have problems when it works.

Tip 4: State

State method is to check the normal working state of each component. If the working state of a component does not conform to the normal state, there is a problem with the device or the affected part. For example, when we check CPU, we will check whether crystal oscillator works normally, reset signal is normal, etc. The input and output logic of the gate is correct to judge whether the device is normal or not. When using this method, the input is often forced to stimulate the signal. For example, the signal generator is used to send a signal to the input end of the operational amplifier, and the output signal amplitude and distortion are measured by oscilloscope to judge the operation and discharge problems. The input level of logic gate circuit is forced to be pushed up or pulled down, and the output level is measured to be in accordance with the logic of the chip, so as to judge the quality of the chip.

State method is the most accurate method of all maintenance methods. Its operation difficulty is not mastered by general engineers. It needs rich theoretical knowledge and practical experience. In order to meet the state requirements, engineers must try their best to test the circuit better than curve scanning. Whether it is the peripheral circuit or the peripheral circuit of IC, it can be found.

Tip 5: Grounded Circuit

The grounded circuits is the method that build up a circuit. The circuit can work after installing the missing integrated circuit, so as to verify the quality of the tested integrated circuit. For example, in order to judge the quality of a 555 integrated circuit, we can build a time-based oscillation circuit made of 555 circuit. And then put the tested integrated circuit in the circuit. If the circuit works normally, It is proved that 555 is OK, and vice versa.

The method can reach 100% accuracy, but the tested IC has many models and complex package, so it is difficult to build all the integrated circuits into one set of circuits.

Tip 6: Principle Analysis

This method is to analyze the working principle of a board. For engineers, some boards such as switching power supply, can know the working principle and details without drawing. It is very simple to know the maintenance of the parts that know the schematic diagram. However, for some relatively complex and rare equipment, without the ready-made schematic reference, we can reverse engineer it manually, draw out the schematic diagram, and then repair it with the schematic diagram, which can be said to be a great success.

The method requires great patience and careful attitude of engineers to complete. One effort can benefit forever. However, whether the method is really adopted depends on the value and quantity of maintenance and the difficulty of doing the work.