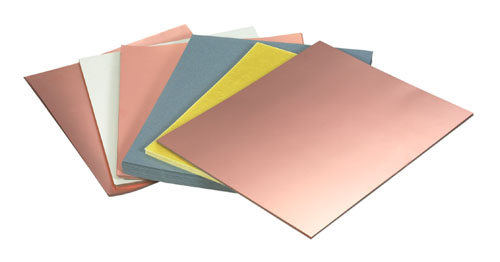

The common substrate materials of printed circuit boards include paper-based CCL, epoxy glass cloth based CCL, composite CCL, metal based CCL, flexible CCL, ceramic substrate, copper-clad polyimide glass fiber cloth laminate and BT resin for high-frequency circuits.

1. Paper Based CCL

Paper based CCL is made of fiber paper + adhesive through drying → copper clad foil → high temperature and high pressure process. Its characteristics are: loose paper base, only punching, not easy to drill; High water absorption; The dielectric and mechanical properties are not as good as epoxy plate; Low price; Only suitable for making single panel. Paper based CCL is mainly used in consumer electronics. During the welding process of paper-based CCL, pay attention to carefully adjust the temperature and pay attention to the drying treatment of PCB, so as to prevent too high temperature and foaming of PCB.

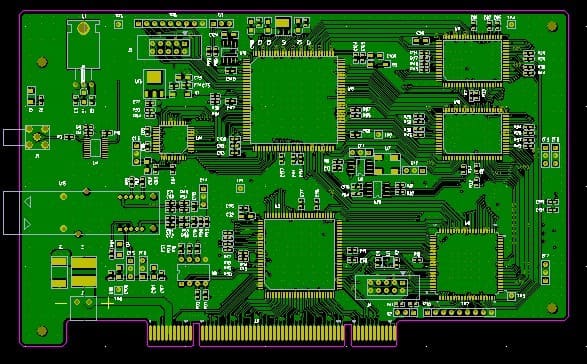

2. Epoxy Glass Cloth CCL

Epoxy glass cloth based CCL is made of epoxy glass fiber cloth + adhesive through drying → copper clad foil → high temperature and high pressure process. Its characteristics are: excellent comprehensive performance; Low water absorption, easy to drill at high speed, good mechanical and electrical properties; It is widely used in double-sided, multi-layer, medium and high-grade electronic products. Epoxy glass cloth copper-clad laminate can be divided into flame retardant and non flame retardant. FR3, FR4 and FR5 are flame retardant, and the inner layer is printed with red marks.

3. Composite CCl (CEM)

The added materials of surface and core are rigid CCL composed of different materials, which is called composite CCL, or CEM for short. There are two main varieties of CEM: CEM-1 and CEM-3.

CEM-1 is improved on the basis of fr-3. Its mechanical strength, moisture resistance, flatness, heat resistance and electrical properties are better than paper-based CCL; It can be used to make PCB with high frequency requirements. It is an ideal substitute for fr-3, mainly single panel.

CEM-3 is improved from FR-4. It replaces most glass fiber cloth with glass non-woven cloth, increases toughness in mechanical properties, and drilling processing is also better than FR-4. The thickness and accuracy of CEM-3 are not as good as FR-4, and the degree of distortion after welding heat is also higher than FR-4. CEM-3 is an approximate product of FR-4, which has great advantages and is suitable for a variety of electronic products.

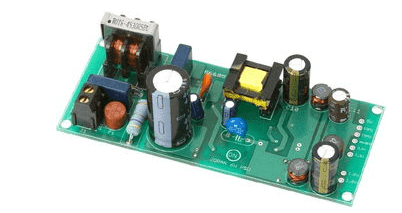

4. Metal Based CCL

Metal based CCL is made of a metal substrate as the bottom layer or inner core, an insulating layer is covered on the metal plate, and the outermost layer is copper foil. Metal substrate plays the role of support and heat dissipation. It is usually used in high-power power board, high-frequency microwave board and load-bearing board. Metal based CCL has two types: metal plate and metal core substrate. The commonly used metal substrates include aluminum substrate, stainless copper substrate, copper substrate, etc. they have good mechanical performance and heat dissipation performance and can shield electromagnetic waves.

5. Flexible CCL

Flexible CCL is made of copper foil on the surface of polymer substrate by high temperature and high pressure process. The flexible printed circuit board (FPC) can be made by etching copper circuit or printing polymer thick film circuit on the flexible CCL. At present, it can be processed into single-sided, double-sided, multi-layer and rigid flex combined FPC. The substrate materials of flexible CCL are mainly polyester film copper clad laminate and polyimide (PI) copper clad laminate.

6. Ceramic Substrate

Ceramic substrates generally use more than 95% high aluminum ceramic substrates, which have the advantages of high temperature resistance, low coefficient of thermal expansion (CTE), no deformation and good chemical stability. They are mainly used in military fields and thick film hybrid circuits. Their disadvantages are difficult drilling and high processing cost.

7. Copper Clad Polyimide Glass Fiber Cloth Laminate for High Frequency Circuit

Copper clad polyimide glass fiber cloth laminate is a composite material composed of polyimide, E-glass cloth and copper foil. The base material is resistant to high temperature and radiation, and has excellent mechanical properties at high temperature; It has excellent high-frequency dielectric properties. At 300mhz-1ghz, the dielectric constant is 4.1 and the dielectric loss factor is 0.007; At the same time, it has excellent dimensional stability and machining performance. Copper clad polyimide glass fiber cloth laminate is the preferred substrate material for high frequency circuits.

8. BT Resin

BT resin is also a thermosetting resin, which was successfully developed by Mitsubishi Gas Chemical Company in 1980. BT resin is usually mixed with epoxy resin to make substrate.