The company uses dry film in the production process, combined with various problems and solutions in the production. Now on the dry film characteristics and application process for an introduction. For your reference in the work.

The Composition of Dry Film

Dry film also known as dry film photoresist. Dry film, composed of the following parts:

Polyester cover film: the thickness of 1 mil, the carrier of the photographic emulsion, the role of the oxygen barrier, peeled off after exposure. (High-temperature resistance)

Photoresist Film: Thickness 1.5 mil, photographic emulsion, dry film body.

Polyethylene film: Thickness 1 mil, prevents the dry film from sticking to each other when it is rolled and peeling off when it is laminated.

Composition of photo emulsion

- Binder: The main component of dry film, is the carrier of other components, and has a certain “steel”, not to cause the film body too much “spread”. Mainly affects the development and the characteristics of the film (refers to solvent-based or water-soluble). Different binders made of dry film can be divided into water-soluble, semi-water-soluble, or solvent-based dry film.

- Photosensitizer: Photosensitive polymerization reaction at the beginning of the appropriate wavelength of light emitted by the light source, “light energy” of the “activation”. The photosensitizer will split itself to release “free radicals”, thus triggering the subsequent photopolymerization process.

- Monomer: An important element in the photopolymerization process. Monomer in the exposure process will react with the previously appeared “free radicals”, and then start a series of transfer polymerization reactions (known as cross-linking reaction)

- Plasticizers and adhesion promoters: The purpose of the two additives is to enhance the flexibility of the dry film and the adhesion or grip between the copper surface.

- Dyes: The purpose is twofold, one is the dry film itself in the manufacture of easy to check: the second is to facilitate the use of graphics used in the production of visual inspection. The most common colors are red, blue, green, purple, and so on. Different dyestuff series can be divided into two types: photographic color enhancement and photographic color fading.

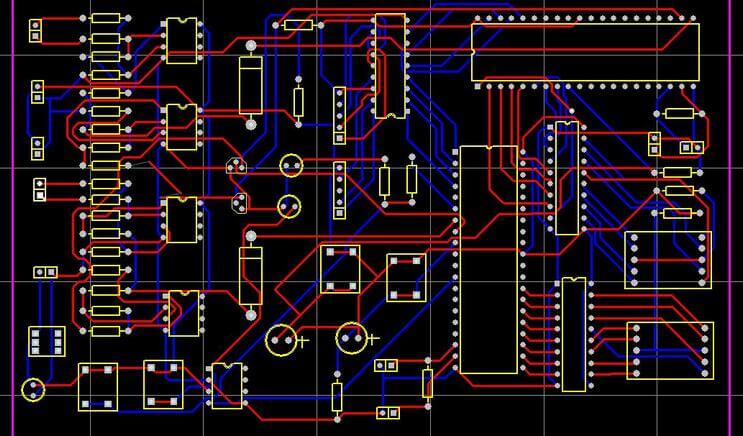

Dry Film Process Flow

Flowchart

Process Principle

Pickling: Use H2so4 to remove the oxidization of the board surface and clean the board surface.

Grinding: Evenly roughen the surface of the board and remove board debris to improve the bonding between the dry film and the copper surface.

Baking: Keep the temperature of the board surface at a certain value before applying the film to ensure that the copper surface and the dry film are closely combined.

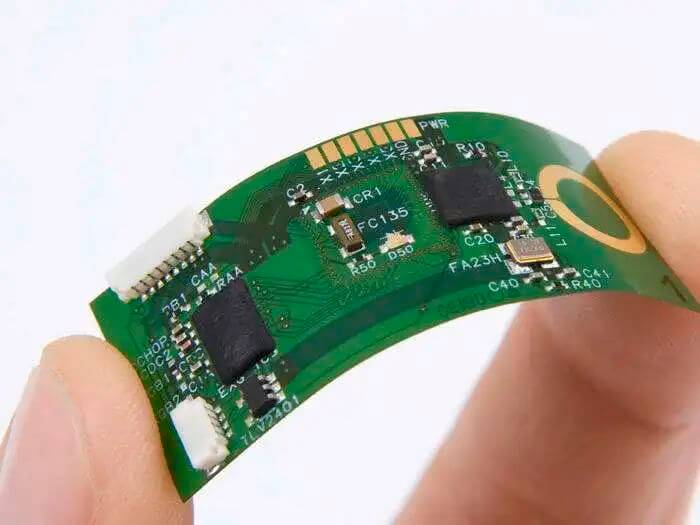

Laminating: Adhere the dry film to the cleaned and roughened copper surface under a certain temperature and pressure.

Alignment: Through the yellow film negative and the corresponding holes in the board surface alignment coincide, to complete the transfer of line graphics work.

Exposure: The use of UV ultraviolet light energy on the dry film for selective sensitization, the film on the line graphics completely transferred to the board surface with dry film.

Developing: Using a certain concentration of Na2CO3 (K2CO3) solution to dissolve the unsensitized part of the dry film to get the required line graphics.

Working environment requirements:

- Temperature: 20 ± 3 ℃; relative humidity: 50—70 ℅.

- Purification room environment requirements: according to different product grades, the purification room environment requirements are different (≤ 10,000, ≤ 100,000, etc.).

- Lighting: Work area lighting using yellow light or white light without UV ultraviolet light.

Test Methods

Abrasion test

Needle reel grinding machine abrasion test:

- Do not open the grinding brush under the condition of the boot, will be a double-sided copper-clad board. Place the dry test required under the grinding brush.

- Turn on the brush for about 3-5 seconds, then turn off the brush.

- Repeat steps 1 and 2 to test the abrasive marks of the four brushes.

- Check the abrasion mark, the width of the abrasion mark is required to be in the range of 12-18MM (a width difference of 5MM or less is acceptable), and 0.5 at each end is not counted.

- Above operation of each circulating pump needs to be opened, the grinding brush swing can not be opened.

Water film rupture test

Will be a good board into the clean water, and then the board vertically in the 45-90 degree angle, observe the water film uniformly retained on the surface of the time.

Exposure energy measurement

- Paste two pieces of exposure ruler on the diazo sheet at the appropriate transparent place. (The company now uses the Stouffer 21step exposure ruler)

- Dual nitrogen sheet pasted to the test plate has been affixed to the dry film (test plate on both sides of one side of a piece).

- Into the exposure machine, vacuum exposure. Exposure to good light after at least 15 minutes of rest before developing.

- After the development of a transparent or yellowish grid that is the test plate of the exposure energy grid (reading two kinds, namely, cover the film and copper, the difference between the first level).

Developing point test

Place a good dry film attached to be exposed to the board in the work of the developer, to be the board to the middle of the developing room, turn off the developer pump, write down the board in the position of the developing cylinder, continue to come out of the wash, according to the board to determine the location of the exposed copper point. The “development point” is the distance from the exposed copper point to the beginning of the development chamber as a percentage of the entire length of the development chamber.

Common Problems and Solutions

| Process | Problems | Causes | Measures to solve the problem |

Millboard |

Oxidizing

| Recirculating water washing is too dirty | Replace the recirculating water wash and clean the water tank |

| Absorbent sponge reel too dirty | Wash or replace the absorbent sponge reel | ||

| Low drying temperature | Check drying temperature | ||

| Conveyor too fast | Adjust conveyor speed | ||

| Insufficient concentration of pickling | Check acid concentration and add | ||

Laminating Film

| Lamination wrinkles | Asymmetry of upper and lower dry film | Re-align the upper and lower dryer sheets |

| Uneven temperature distribution | Measure reel temperature and calibrate | ||

| Uneven pressure | Inform maintenance of adjustments | ||

| Diaphragm | Insufficient pressure | Adjust air pressure | |

| Insufficient or too high temperature | Adjust temperature | ||

| Conveyor speed is too fast | Adjust speed | ||

| Exposure | Poor exposure

| Bad vacuuming | Increase the evacuation pressure and manually assist in catching air |

| Exposure energy is too high or insufficient | Redo the exposure scale or adjust the exposure energy | ||

| Yellow film optical density does not reach the forest requirements | Check the optical density of the yellow film or repeat the yellow film | ||

| Expose (a photographic plate) |

Overdevelopment

| Developing point is too low | Re-adjust the developing point |

| The temperature of the solution is too high | Turn on the cooling system to lower the temperature | ||

| The concentration of water is too high | Adjust the concentration of water according to the laboratory report | ||

| Developing pressure is too large | Re-adjust the developing pressure | ||

Poor development | Developing point is too high | Re-adjust the developing point | |

| Too low temperature of water | Warm up the developer to the required range and then develop the image. | ||

| Concentration of water is not enough | According to the test result, add developer solution to the process range. | ||

| Too many developer plates | Replace the developer with new one and control the number of developer plates. | ||

| Nozzle clogging | Check whether the nozzle is clogged and unclog it. |