The entire power electronics industry, including radio frequency applications and systems involving high-speed signals, is moving towards solutions that provide increasingly complex functions in ever smaller spaces. Designers are faced with increasingly demanding challenges in meeting system size, weight and power requirements, including effective thermal management, which again starts with the design of the PCB.

Highly integrated active power devices such as MOSFET transistors dissipate a lot of heat, requiring the PCB to be able to transfer heat from the hottest components to ground planes or cooling surfaces to operate as efficiently as possible. Thermal stress is one of the main causes of power device failure as it leads to performance degradation and can even lead to system failure or failure. The rapid increase in device power density and the continuous increase in frequency are the main reasons for the overheating of electronic components. Semiconductors with lower power loss and better thermal conductivity, such as wide-bandgap materials, are increasingly used, but by themselves they are not sufficient to eliminate the need for effective thermal management.

Current achievable junction temperatures for silicon-based power devices are between approximately 125°C and 200°C. However, it is always best to operate the device below this extreme condition to avoid rapid aging of the device and shorten its remaining lifetime. In fact, it is estimated that a 20°C increase in operating temperature due to poor thermal management can reduce the remaining lifetime of components by as much as 50%.

PCB Layout Method

A common approach to thermal management in many projects is to use a substrate with a standard flame retardant rating of 4 (FR-4), which is an inexpensive and easy-to-process material that focuses on thermal optimization of the circuit layout.

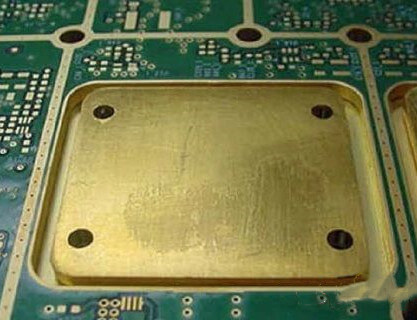

The main measures taken involve providing extra copper surface, using thicker traces, and inserting thermal vias under the components that generate the most heat. A more radical technique that dissipates more heat involves inserting actual copper slugs into the PCB or applied to the outermost layer, usually in the shape of a coin, hence the name “copper coin”. After the copper coin is processed separately, it can be soldered or directly attached to the PCB, or it can be inserted into the inner layer and connected to the outer layer through the heat dissipation hole. A special cavity is made in the PCB shown in Figure 1 to accommodate a copper coin.

Copper has a thermal conductivity of 380W/mK, compared to 225W/mK for aluminum and 0.3W/mK for FR-4. Copper is a relatively inexpensive metal that is widely used in PCB manufacturing; therefore, it is ideal for copper coins, thermal vias, and ground planes—all solutions that improve heat dissipation.

Proper placement of active components on the board is a key factor in preventing hot spots from forming, thereby ensuring that heat is distributed as evenly as possible across the board. In this regard, active components should be distributed around the PCB in no particular order to avoid hot spots in certain areas. However, it is best to avoid placing active components that generate a lot of heat near the edge of the board. Instead, place them as close to the center of the board as possible to facilitate even heat distribution. If high-power components are mounted near the edge of the board, heat will build up at the edge, increasing the local temperature. On the other hand, if you place it near the center of the board, the heat will be dissipated in all directions along the surface, making it easier to reduce the temperature and allow the heat to dissipate more easily. Power devices should not be placed close to sensitive components, and should be properly spaced from each other.

Measures taken at the layout level can be further improved by employing active cooling and passive cooling systems such as heat sinks or fans – systems that remove heat from active components rather than dissipating it directly into the circuit board. In general, designers must find an appropriate compromise between different thermal management strategies based on the requirements of a particular application and the available budget.

PCB Substrate Selection

Due to its low thermal conductivity (between 0.2 and 0.5W/mK), FR-4 is generally not suitable for applications that need to dissipate a lot of heat. The heat generated in high power circuits can be considerable, and these systems often operate in harsh environments and extreme temperatures. Using an alternative substrate material with higher thermal conductivity may be a better option than using conventional FR-4.

For example, ceramic materials offer significant advantages for thermal management of high-power PCBs. In addition to improving thermal conductivity, these materials have excellent mechanical properties that help compensate for stresses that build up during repeated thermal cycling. In addition, ceramic materials have low dielectric loss at frequencies up to 10 GHz. For higher frequencies, there is always the option of a hybrid material such as PTFE, which offers the same low losses but with a modest reduction in thermal conductivity.

The higher the thermal conductivity of the material, the faster the heat transfer. Therefore, metals such as aluminum, in addition to being lighter than ceramics, offer an excellent solution for transferring heat away from components. Aluminum in particular is also an excellent conductor, has excellent durability, is recyclable, and is non-toxic. The metal layer helps transfer heat quickly across the board due to its high thermal conductivity. Some manufacturers also offer metal-clad PCBs, where both outer layers are metal-clad, usually aluminum or galvanized copper. From a cost-per-weight standpoint, aluminum is the best choice, while copper has a higher thermal conductivity. Aluminum is also widely used to make PCBs that support high-power LEDs (as shown in the example in Figure 2), where its ability to reflect light away from the substrate is particularly useful.

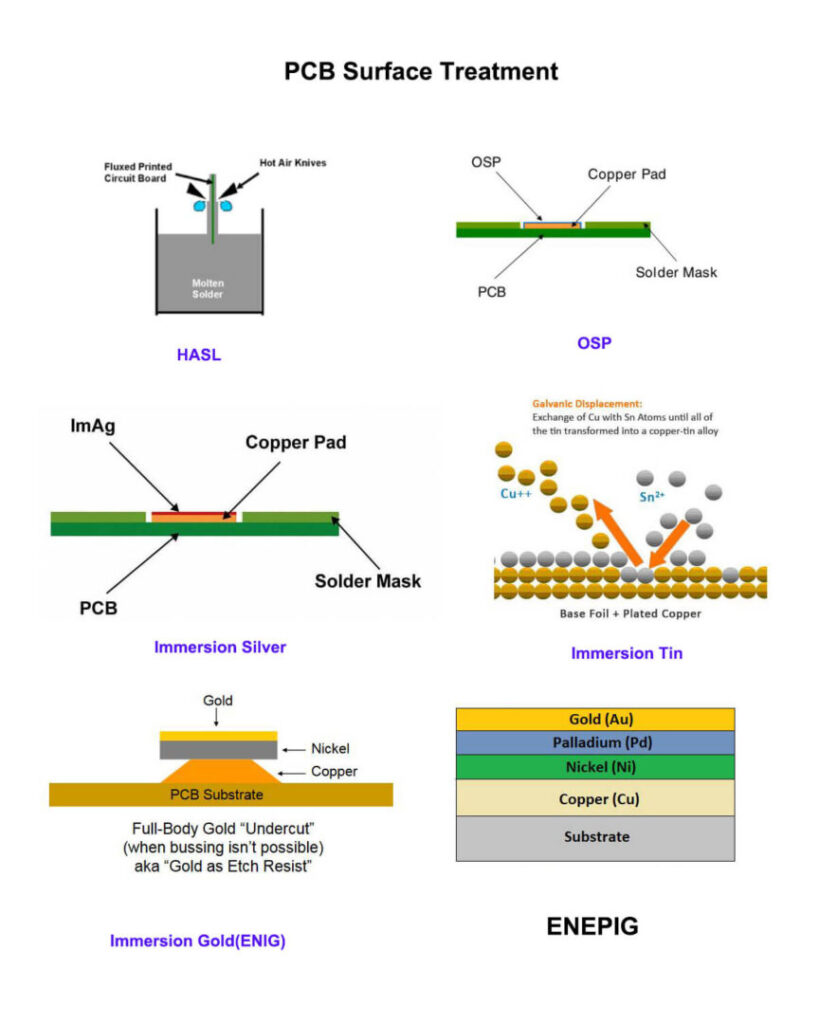

Even silver, which has about 5 percent higher thermal conductivity than copper, can be used for traces, vias, pads and metal layers. Also, if the board is used in a humid environment where toxic gases are present, using a silver finish on exposed copper traces and copper pads will help prevent corrosion – a typical known threat in such environments.

Metal PCBs, also known as insulated metal substrates (IMS), can be laminated directly into a PCB to form a board with an FR-4 substrate and a metal core. It uses single-layer and double-layer technology, with depth-controlled routing, which can transfer heat from on-board components to less critical areas. In an IMS PCB, a thin layer of thermally conductive but electrically insulating dielectric is laminated between a metal base and copper foil. The copper foil is etched into the desired circuit pattern, and the metal base absorbs heat from the circuit through this thin dielectric.

The main advantages offered by IMS PCB are as follows:

- The heat dissipation is significantly higher than standard FR-4 structure.

- The thermal conductivity of the dielectric is typically 5 to 10 times higher than ordinary glass epoxy.

- The efficiency of heat transfer is much higher than traditional PCB.