The biggest difference between flexible electronic printing and printed circuit board is that the current carrying capacity of wires is different. The heat dissipation capacity of flexible electronic printing is relatively poor, so the current carrying capacity it can bear is relatively small; The heat dissipation capacity of printed circuit board is relatively strong, and its current carrying capacity is naturally relatively large. In addition, there are differences in flexibility between the two. The flexibility of flexible electronic printing is better, while the flexibility of printed circuit board is worse.

1. Principle of Flexible Electronic Printing

The working principle of flexible electronic printing is realized through printing technology, because printing technology can replace the ink with heavy color with the ink with electronic function, so as to achieve the purpose of reproducing electronic function. Moreover, the flexibility of flexible electronic printing is better, which can make the printed pattern clearer. However, due to the high cost and energy consumption of flexible electronic printing, and the non environmental protection of flexible electronic printing, the scope of application is also relatively narrow.

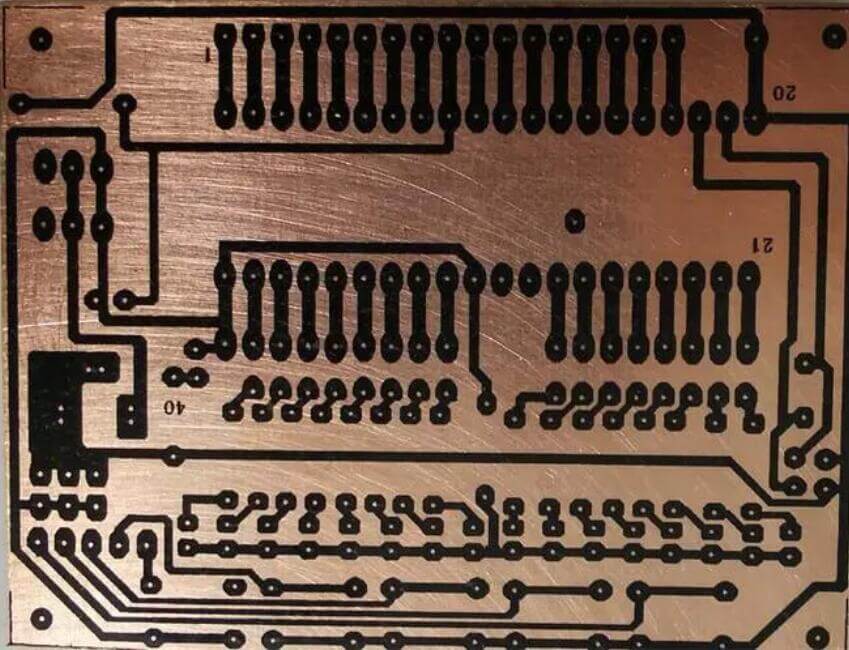

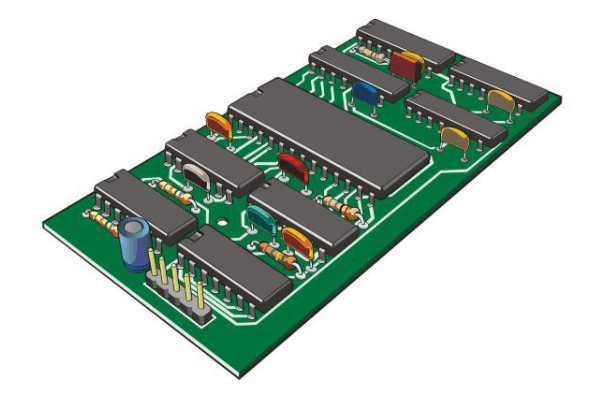

2. What are The Components of a Printed Circuit Board?

The printed circuit board is composed of circuit, dielectric layer, hole and anti welding ink. Circuit is the most basic part of printed circuit. If it is missing, the printed circuit board will not work. The dielectric layer mainly plays an insulating role, so that each line can operate normally. Holes in printed circuit boards, also known as through holes, allow individual circuits to be connected. Anti soldering ink can play a role of eating tin parts to prevent short circuit of non tin lines.

3. What Are The Manufacturing Methods of Printed Circuit Board?

The manufacturing methods of printed circuit board include addition method, subtraction method and accumulation method. The subtraction method is to put chemicals into the blank part of the circuit board and then use gold and tin foil to get the desired circuit. The addition method needs to first coat a thin layer of copper on the circuit board, and then irradiate it under ultraviolet light. After the required places are exposed, the unnecessary places can be removed. The lamination method is mainly used to make multilayer printed circuit boards, which is not widely used.