What is PCBA?

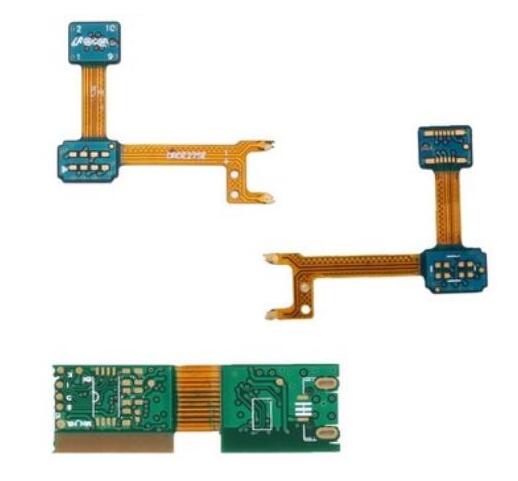

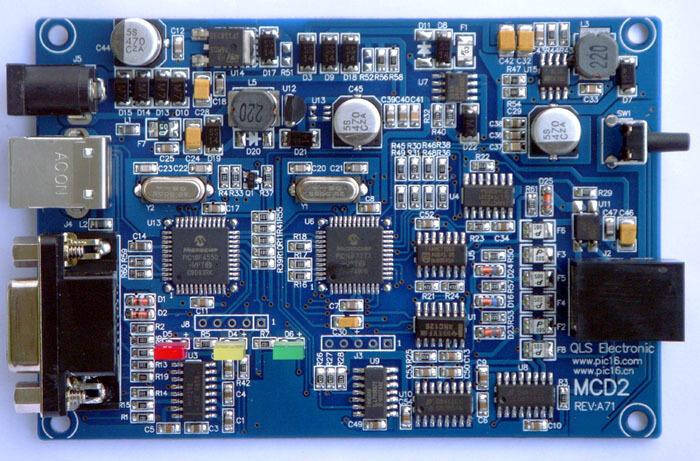

PCBA is assembly of PCB. Various electronic devices are assembled on the circuit board by surface packaging process. Next is box assembly, which will assemble the assembled PCB with the shell to form the finished product. PCB blank board passes SMT upper part, then passes through the whole process of dip plug-in, or PCBA. This is a common method in China, while the standard writing method in Europe and America is “pcb’a”, which is added with oblique points. PCBA is a PCB with a chip attached.

What is PCBA Test?

PCBA test refers to the test of IC burn, line on and off, current, voltage, pressure and so on.

Why Need to Do PCBA Test?

PCBA has many uncontrollable factors in the production process, it is difficult to ensure that PCBA is a good product, and PCBA testing is a necessary link to strictly control the quality of delivery.

What Tests Does PCBA Test Include?

According to different products and different customer requirements, PCBA test will be different. Generally speaking, PCBA test includes ICT online test, FCT function test and aging test.

PCBA Test Process

Generally the specific test process is formulated according to the customer’s test plan. The basic PCBA test process is as follows:

Procedure Burning → ICT Test → FCT Test → Aging Test

- Program Burn

After the welding and processing of PCBA board is completed, engineers start to burn the program of the single chip microcomputer in PCBA board, so that the MCU can realize specific functions.

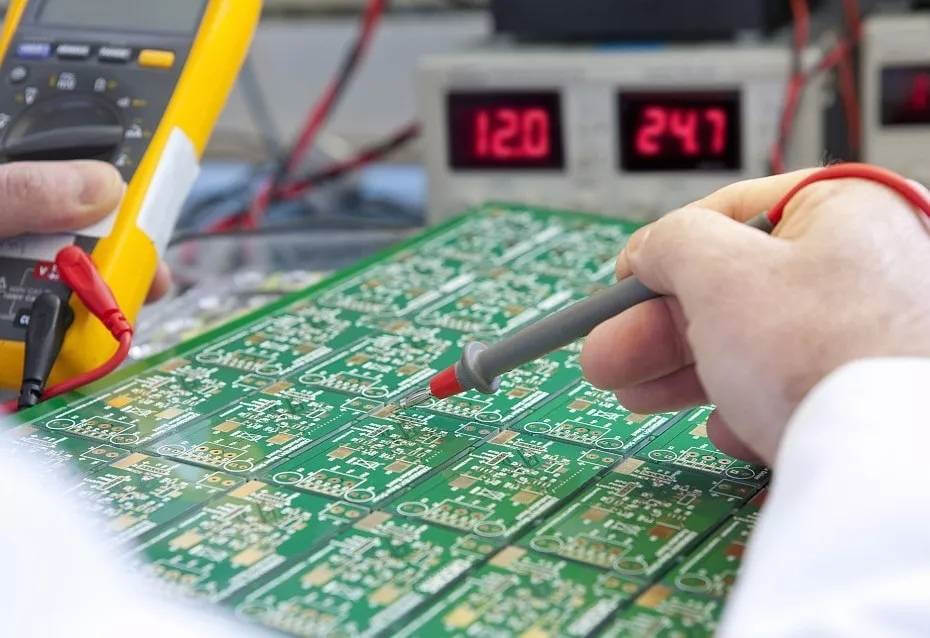

- ICT Test

ICT test through the test probe contact the test point of PCBA, to achieve the test of the open circuit, short circuit and the welding of electronic components. ICT test is more accurate, clear indication and wide range of use.

- FCT Test

FCT test can test the parameters of PCBA environment, current, voltage, pressure, etc. the test contents can ensure that all parameters of PCBA board meet the design requirements of the designer.

- Aging Test

The aging test can ensure the stability of the product by continuously energizing PCBA board, simulating the user’s use scene, detecting some defects that are not easy to find, and testing the service life of the product.

Metal materials will produce different residual stresses in the process of machining and hot working. The existence of residual stress has a significant impact on the mechanical properties of materials. Therefore the detection of residual stress is of great significance for the heat treatment process, surface strengthening process, the effect of stress relief process and the control and analysis of defective products.

Steps of PCBA Stress Test

Firstly, the strain gauge is pasted on several different positions of PCB. And connected to the measuring instrument system through the strain gauge during the process or work station operation, so that the stress can be quantitatively displayed and recorded.

That is: strain resistance change voltage (or current) change amplification record data processing

Strain—Resistance Change—Voltage (or Current) Change—Zoom In—Record—Data Processing

- Select Strain Gauge

Strain gauge is a kind of sensor which can change the resistance value linearly according to the stress. When the strain gauge is deformed, the resistance value will change accordingly.

- Sticking Strain Gauge

According to the process to be tested, PCBA real board is selected, and according to the position of stress, the test point on PCB is selected and the strain gauge is pasted. If there is not enough space to paste the strain gauge on the board, the parts fixed on the board have to be removed to make room. In general, at least two or three PCBAs to be tested should be installed and tested to prove the correctness and consistency of the test.

- Measuring Strain

Connect the lead of the strain gauge to the data acquisition instrument of the test system, adjust the scanning frequency (also known as sampling rate), sampling resolution, gain setting, excitation voltage, number of channels and other parameters, and run the test program. The test time is variable, generally 5-10 seconds and record the data.

For PCBA plate strain test, it is recommended that the scanning frequency range is 500hz-2khz. Generally, a higher frequency should be selected as far as possible to capture the instantaneous stress change.

- Analysis of Recorded Data

Analyze the collected strain data, calculate the stress of PCBA during the test (, large stress and small stress), and record all the data.