How to Inspect Short Circuit of PCB Board ?

- If it is manual welding, we should develop good habits

- Before welding, the PCB board shall be inspected visually and the key circuits (especially power supply and ground) shall be checked for short circuit with multimeter.

- After welding a chip, use a multimeter to test whether the power supply and ground are short circuited.

- Do not throw soldering iron randomly during welding. If solder is thrown on the chip welding feet (especially the surface mounting element), it is not easy to find.

- Open PCB diagram on computer, light up short circuit network, and see where nearest, it is most easy to connect to one piece. Pay special attention to the internal short circuit of IC.

- A short circuit was found. Take a board to cut the line (especially suitable for single / double layer board). After cutting, power on each part of the functional block, and exclude some parts.

- Using short circuit positioning analyzer

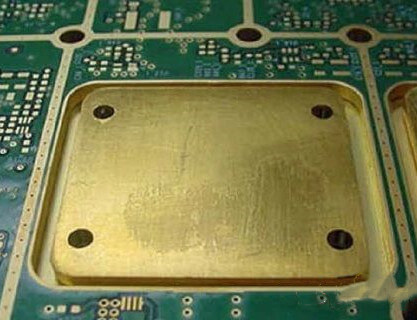

- If BGA chip is available, because all welding points are covered by the chip and are multi-layer board (more than 4 layers), it is better to separate the power supply of each chip in design and connect with magnetic bead or 0 ohm resistance. In case of short circuit between power supply and ground, it is easy to locate a chip by breaking magnetic bead detection. Because of the difficulty of BGA welding, if it is not automatic welding of machine, the adjacent power supply will be short circuited to the two welding balls on the ground if it is not automatic welding.

- When welding small scale surface mount capacitance, it is necessary to be careful, especially the filter capacitance of power supply (103 or 104). The number is too large, which is easy to cause short circuit between power supply and ground. Of course, sometimes bad luck, will encounter the capacitor itself is short circuit, so the best way is to weld before the capacitance detection.

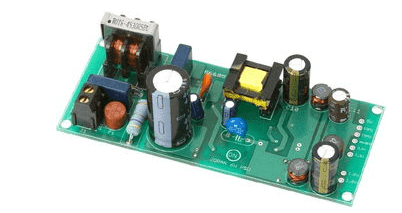

How to Judge PCB Board is OK?

Distinguish The Quality of The Circuit Board From The Appearance

Generally, the appearance of PCB circuit board can be analyzed and judged from three aspects:

- Standard rules for size and thickness.

The thickness of PCB to standard circuit board is different. Customers can measure and check according to the thickness and specification of their products.

- Light and color

The external circuit board is covered with ink, and the circuit board can play an insulation role. If the color of the board is not bright, little ink, the insulation board itself is not good. - Weld appearance

Because of the large number of parts, if the welding is not good, the circuit board which is easy to fall off of the parts seriously affects the welding quality of the circuit board, good appearance, careful identification and stronger interface is very important.

High Quality PCB Board Shall Meet The Following Requirements

- It is required that the telephone can be used better after the components are installed, that is, the electrical connection shall meet the requirements.

- The line width, line thickness and line distance of the line meet the requirements to avoid heating, open circuit and short circuit of the line.

- The copper skin is not easy to fall off under high temperature.

- Copper surface is not easy to oxidize, affecting the installation speed, and it will be damaged soon after oxidation.

- No additional electromagnetic radiation.

- The appearance is not deformed, so as to avoid deformation of the shell after installation and dislocation of screw hole. Now, it is mechanical installation, and the hole position of circuit board and the deformation error between circuit board and design should be within the allowable range.

- The high temperature, high humidity and special environment should be considered.

- The mechanical properties of the surface shall meet the installation requirements.