Understand the composition and classification of printed circuit board, learn more and find information.

Composition

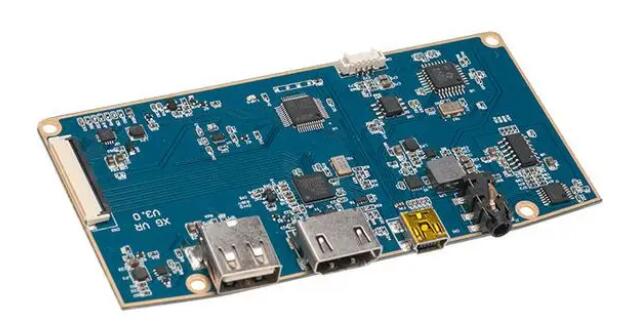

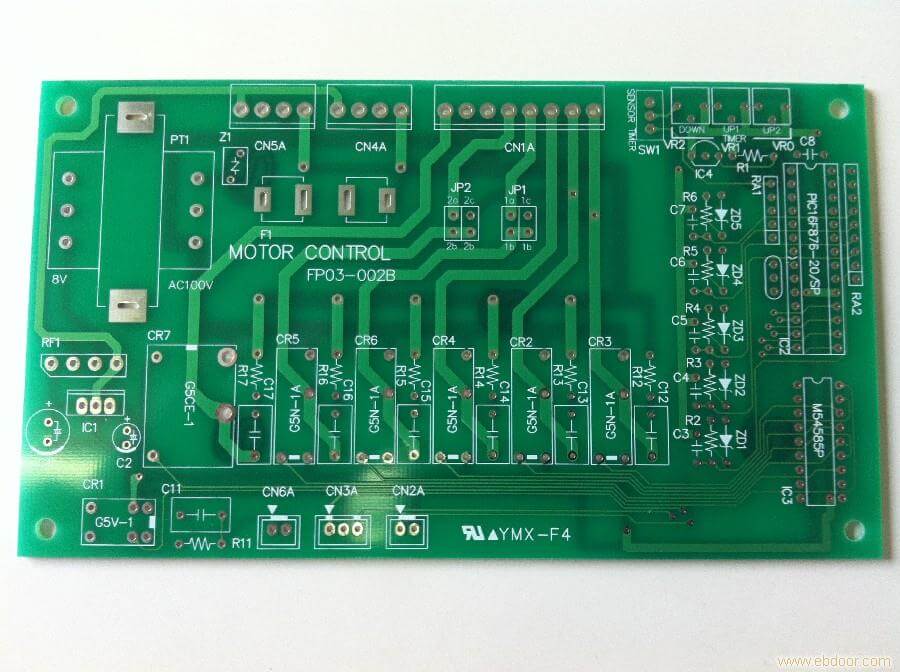

The circuit board is mainly composed of pads, vias, mounting holes, wires, components, connectors, fillers, electrical boundaries, etc. the main functions of each component are as follows:

- Pad: A metal hole used to weld pins of components.

- Vias: There are metal vias and nonmetal vias. Metal vias are used to connect component pins between layers.

- Mounting Hole: Used to fix the circuit board.

- Wire: Copper film of electrical network used to connect component pins.

- Connector: Used for connecting components between circuit boards.

- Filling: Used for copper coating of ground wire network, which can effectively reduce the impedance.

- Electrical Boundary: Used to determine the size of the circuit board, all components on the circuit board can not exceed the boundary.

Main Classification

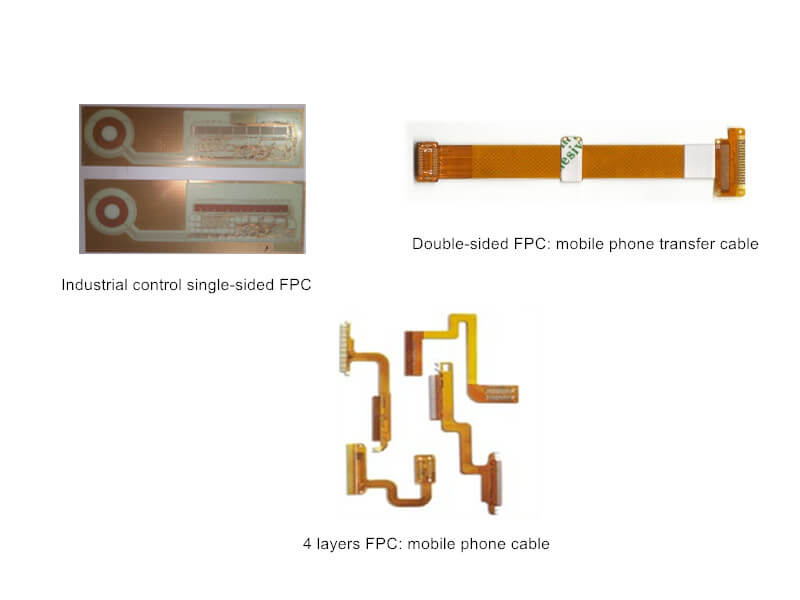

There are several types of printed circuit boards systems

Single-sided Board

Because there are many strict restrictions on the design circuit of a single panel (because there are only one side, the wiring can not cross each other, but must go around its own path), only the early circuits used this kind of board.

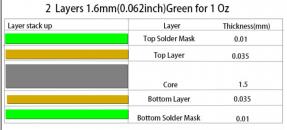

Double-sided Board

This circuit board has wiring on both sides. However, to use two sides of the wire, it is necessary to have a proper circuit connection between the two sides. The bridge between these circuits is called via. A pilot hole is a small hole in a PCB filled with or coated with metal, which can be connected with wires on both sides. Because the area of the double-sided board is twice as large as that of the single panel, and because the wiring can be staggered with each other (can be wound to the other side), it is more suitable for more complex circuits than the single panel.

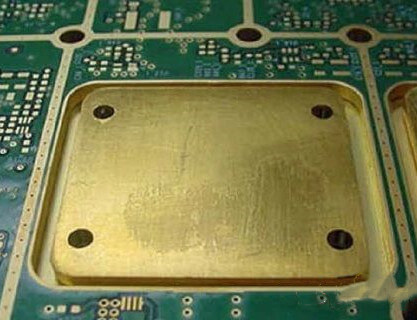

Multi-layer Board

Multi-layer board in complex application requirements, the circuit can be arranged into multi-layer structure and pressed together, and through-hole circuits are arranged between the layers to connect the circuits of each layer.

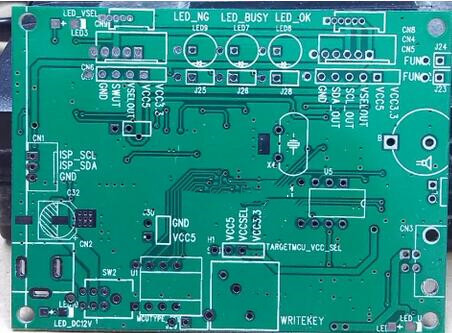

Inner Line

The copper foil substrate is first cut into the size suitable for processing and production. Before pressing the film on the substrate, it is usually necessary to roughen the copper foil by brushing, grinding, micro etching and other methods, and then attach the dry film photoresist to it with appropriate temperature and pressure. The substrate pasted with dry film photoresist is exposed in the ultraviolet exposure machine. After the photoresist is irradiated by ultraviolet light in the light transmission area of the negative, polymerization reaction will occur (the dry film in this area will be retained as an etching resist in the later development and copper etching steps), and the line image on the negative will be transferred to the dry film photoresist on the plate surface. After tearing off the protective adhesive film on the film surface, develop and remove the non illuminated area on the film surface with sodium carbonate aqueous solution, and then corrode and remove the exposed copper foil with hydrochloric acid and hydrogen peroxide mixed solution to form a circuit. Finally, the dry film was removed by sodium hydroxide solution. For the inner circuit board with more than six layers, the riveting reference hole for the alignment of the inter layer circuit is punched by the automatic positioning punching machine.

4 Layers Circuit Board

In order to increase the area of wiring, multi-layer boards use more single or double-sided wiring boards. Multilayer board uses several pieces of double-sided board, and put a layer of insulating layer between each layer of board, then stick (press). The number of layers of a board represents that there are several independent wiring layers. Generally, the number of layers is even and includes the outermost two layers. Most motherboards are 4 to 8-layer structure, but the technology can achieve nearly 100 layers of PCB. Most large supercomputers use multi-layer motherboard, but because this kind of computer can be replaced by many ordinary computer clusters, the multi-layer motherboard has been gradually not used. Because the layers of PCB are closely combined, it is not easy to see the actual number, but if you carefully observe the motherboard, you may be able to see it.