Drilling is a very important part in the manufacturing process of PCB. The quality of drilling greatly affects the functionality and reliability of PCB. However, many customers still don’t know the meanings and characteristics of the through holes, blind holes and buried holes in high-density HDI boards. Let’s have a look.

Vias

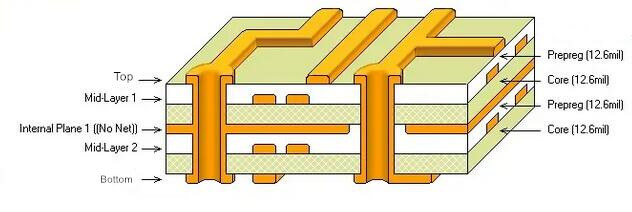

First of all, the circuit board is composed of layers of copper foil circuits, and the communication between different circuit layers depends on vias.

Vias are one of the important components of multi-layer PCB, especially for high-density and high-speed multi-layer PCB (HDI) design, the design of vias needs to attract the attention of engineers. Next, let’s walk into the ocean of vias in PCB design and appreciate the charm of knowledge.

Types of Vias

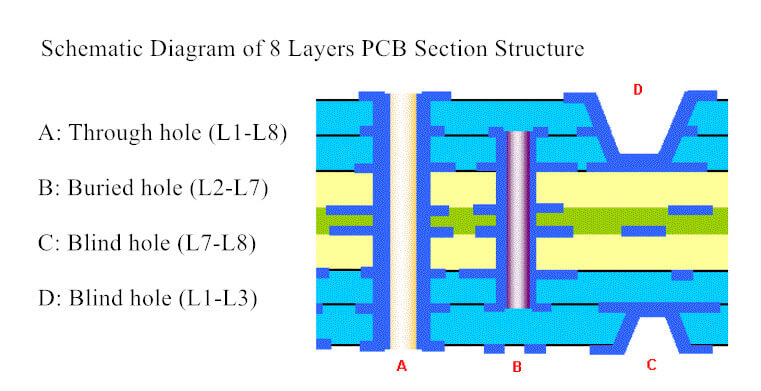

Blind Hole: It is located on the top and bottom surface of the printed circuit board and has a certain depth. It is used to connect the surface circuit with the inner circuit below.

Buried Hole: Refers to the connection hole located in the inner layer of the printed circuit board, which will not extend to the surface of the circuit board.

Through Hole: This kind of hole passes through the whole circuit board and can be used to realize internal interconnection or as the installation and positioning hole of components.

With the increasing high-speed and miniaturization of information products such as mobile phones and notebook computers, and the continuous improvement and acceleration of the integration of semiconductor integrated circuits, the technical requirements for printed boards are higher. The wires on the printed board are thinner and narrower, the wiring density is higher and higher, and the holes on the printed board are smaller and smaller.

Laser blind hole is one of the key technologies of HDI. The characteristics of small aperture and large number of laser blind holes are an effective way to realize high linear density of HDI board. Because there are many laser blind holes as contact points in HDI board, the reliability of laser blind holes directly determines the reliability of products.

Methods for Judging The Reliability of Blind Holes

What kind of blind hole is good? We can judge from the following two aspects.

1. Pass type

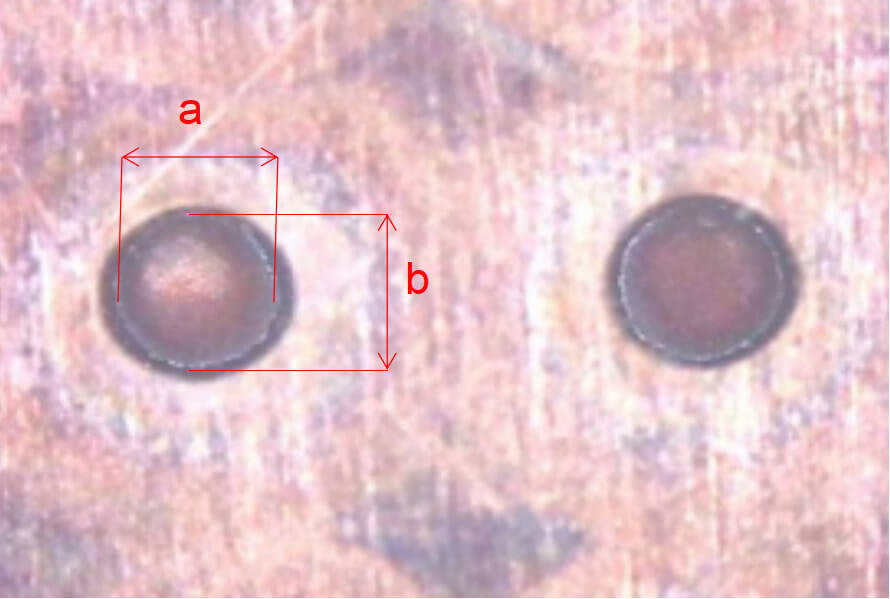

Pass is generally divided into plane pass and cross-section pass.

(1) The plane pass is mainly judged by the true roundness index.

True roundness = short diameter a / long diameter b * 100%.

In general, the true roundness will be required to be ≥ 90%, but it will be adjusted according to the actual situation.

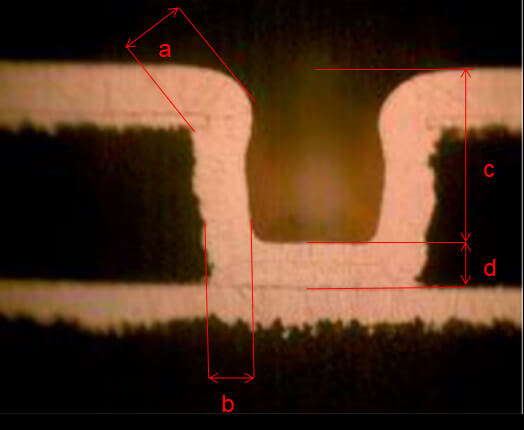

(2) For the cross-section pass, the destructive test must be carried out, the slices must be cut, and the observation and measurement must be carried out. The main indicators include taper, roughness of hole wall, damage degree of substrate copper, etc.

- In general, a = taper ≥ 85%, but B = taper will be adjusted according to the actual requirements.

- The roughness of hole wall # C is generally required to be ≤ 15 for blind holes μ m. However, the actual situation may be different according to different materials.

- In general, the damage degree D of base metal copper is required to be ≤ 1/3 of the thickness of base metal copper, but it will be adjusted according to the actual situation.

Note: As grinding and slicing may lead to change of pass type, these items are usually confirmed by slicing after copper plating.

2. Copper plating condition

The key indicators to measure the copper plating condition are: corner copper thickness, hole wall copper thickness, hole filling height (bottom copper thickness), dimple value, etc.

- The corner copper thickness A mainly represents the thinnest copper plating point. As the measuring points and methods are not unified in the industry, there is no clear standard yet.

- The copper thickness of hole wall B is similar to that of through hole. If the hole is not filled, it is generally compared with the through hole standard. If the hole is filled, there are many influencing factors, and there is no unified standard in the industry.

- The filling height (bottom copper thickness) D is similar to the surface copper thickness of the through hole, which can be compared with the surface copper standard of the through hole to a certain extent.

- Dimple value C refers to the depression value after hole filling. Only hole filling electroplating has the requirement of dimple value, which is difficult to process, and the general requirement in the industry is ≤ 15 μ m.

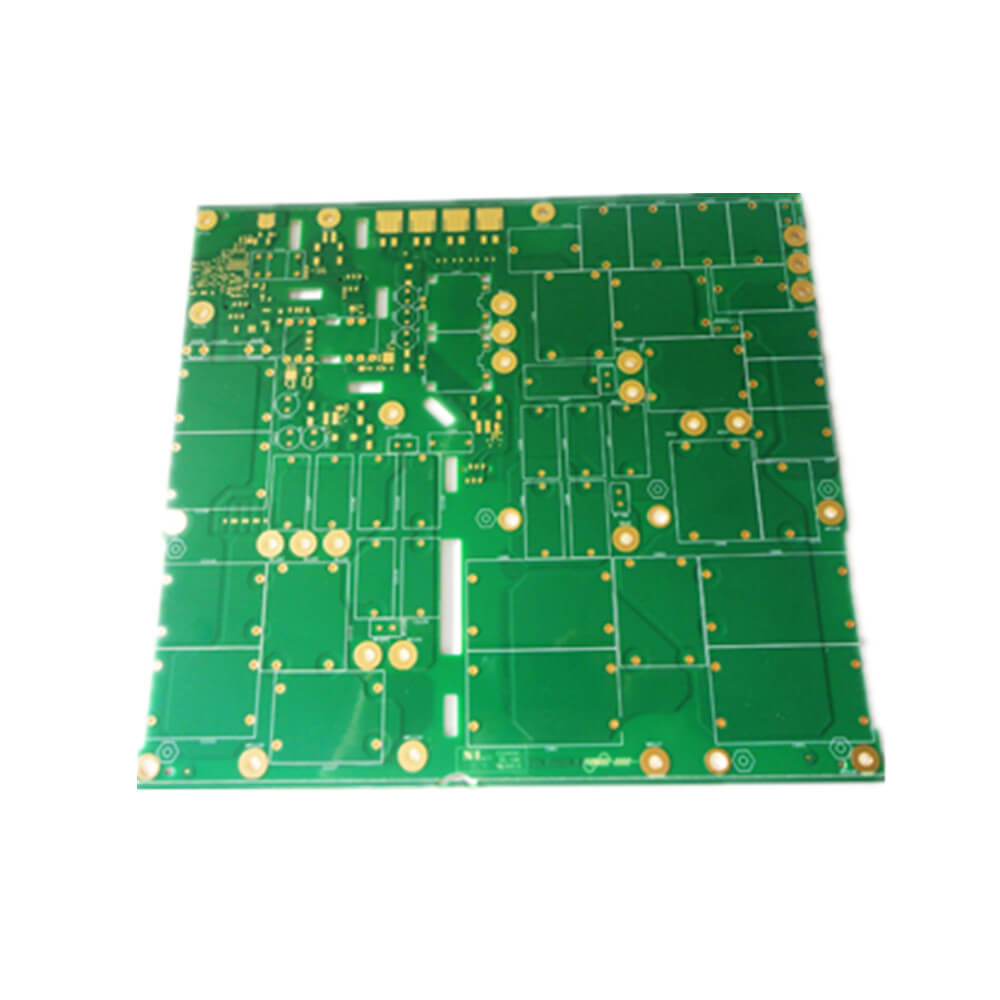

The above describes how to judge the reliability of blind holes. HDI board has many manufacturing processes and complex processes. When manufacturing, first select the process flow, clarify the key technology of manufacturing, and control the aperture and pass type; Reasonable proportion of electroplating solution composition; Pay attention to the filling rate and sag to ensure the hole filling effect.

Olinapcb can make corresponding blind holes according to the general standards in the industry to ensure the flatness, and the dimple value can be controlled at 15 μ Within M. Welcome customers to olinapcb for pcb making, and personally experience the proofing experience of high reliability and short delivery period.