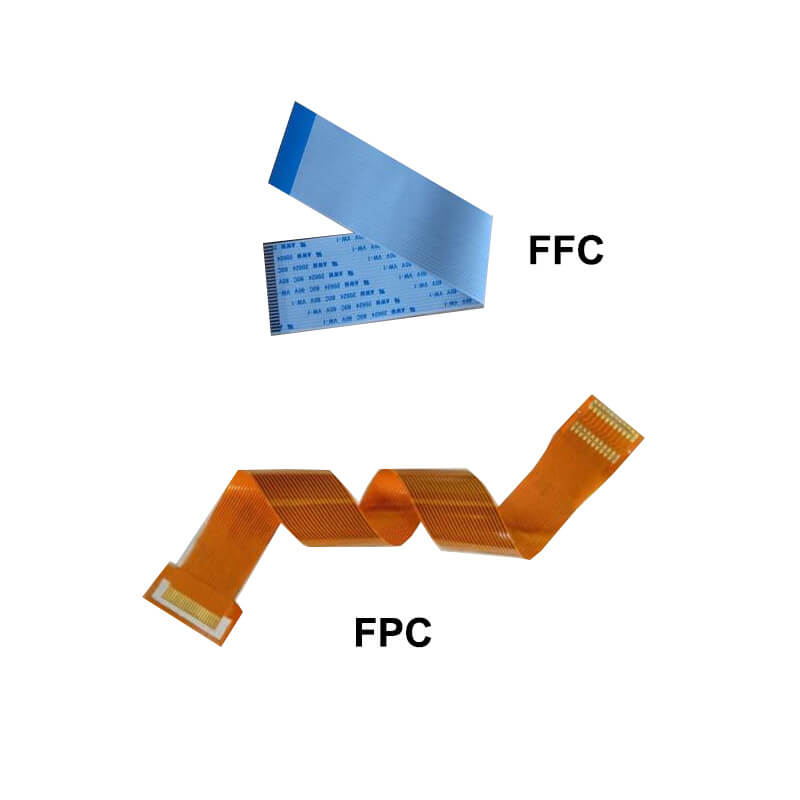

With the continuous development of science and technology, all fields have realized intelligence, so FPC circuit boards have also been widely used in all fields. With the continuous increase of FPC manufacturers, it is natural that some businesses will cheat on price and quality. Then the problem comes, how to judge the good and bad of FPC circuit boards? Here are two ways to judge whether an FPC circuit board is good or bad.

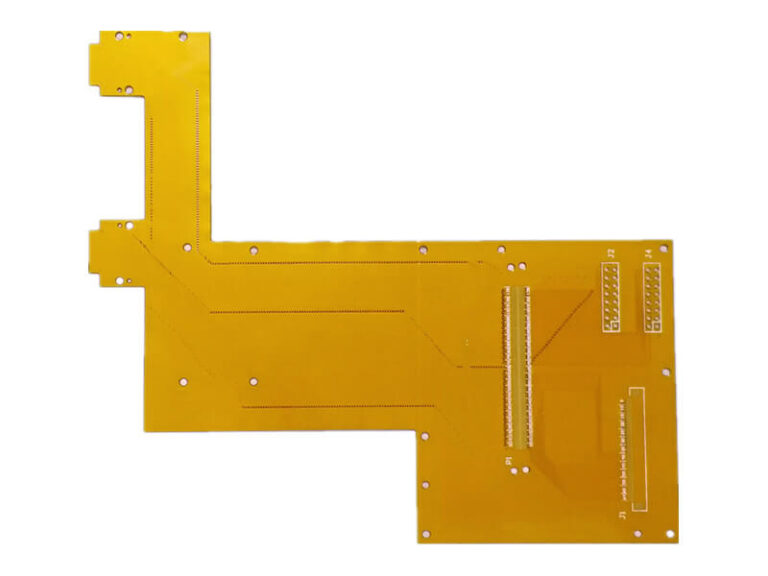

1. Distinguish the good and bad circuit boards from the appearance

In general, the appearance of FPC circuit board can be analyzed and judged from three aspects.

- Standard rules for size and thickness.

The thickness of the circuit board is different from that of the standard circuit board. Customers can measure and check the thickness and specifications of their own products. - Light and color

The external circuit board is covered with ink, and the circuit board can play the role of insulation. If the color of the board is not bright, less ink, the insulation board itself is not good. - Weld appearance

Because there are many parts on the circuit board, if the welding is not good, the parts are easy to fall off, which will seriously affect the welding quality of the circuit board. It is very important to carefully identify the good appearance and the strong interface, which are used to distinguish the good and bad FPC circuit boards.

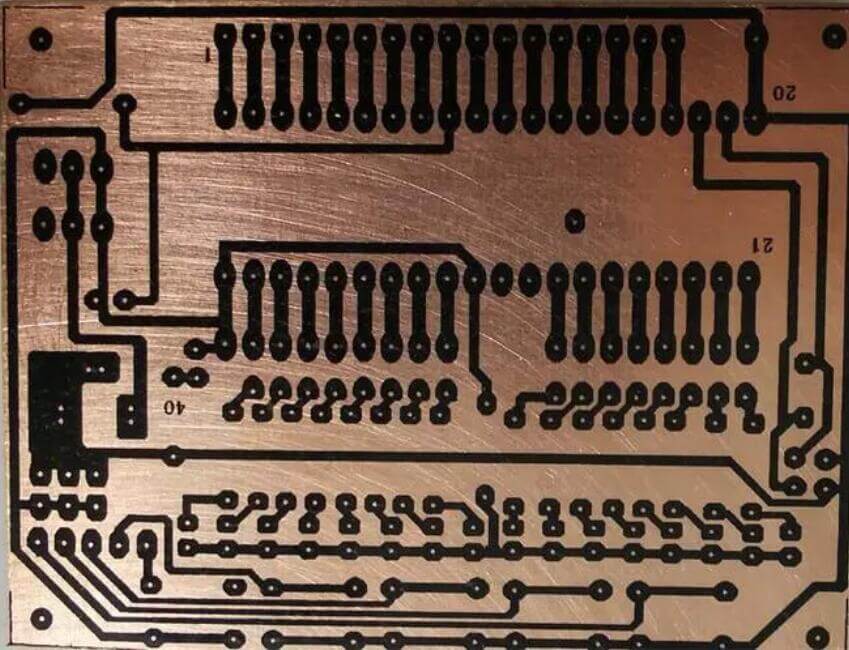

2.High quality FPC circuit boards need to meet the following requirements

- It is required that the telephone should be easy to use after the components are installed, that is, the electrical connection should meet the requirements;

- The line width, thickness and distance of the line shall meet the requirements to avoid heating, open circuit and short circuit of the line;

- The copper sheet is not easy to fall off under high temperature;

- The copper surface is not easy to be oxidized, which affects the installation speed, and it will be damaged soon after oxidation;

- No additional electromagnetic radiation;

- The appearance is not deformed to avoid deformation of the housing and dislocation of screw holes after installation. Now it is all mechanized installation, and the hole position of the circuit board and the deformation error between the circuit and the design should be within the allowable range;

- And high temperature, high humidity and special resistance should also be considered;

- The mechanical properties of the surface shall meet the installation requirements;

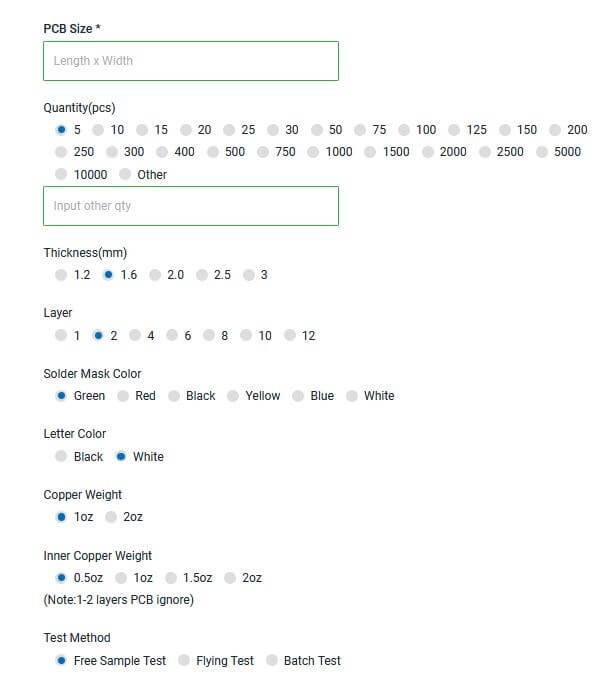

The above is the way to judge whether FPC circuit boards are good or bad. When you buy FPC circuit boards, you must keep your eyes peeled. Olinapcb provides production services for FPC single and double-sided boards, FPC multilayer boards and soft and hard composite boards. Our FPC circuit board proofing time is 3-4 days, and we also provide 24-hour fast and urgent proofing service. The delivery time of FPC batch is 7-10 days. If you have any questions about FPC, please call or consult online services for more information.