Soldering is an important step in the production of electronic equipment. After soldering, there are always varying degrees of flux residues and other types of contaminants on the circuit board surface, even if a low-solid content, halogen-free, no-clean flux is used. There will still be more or less residue. In order to prevent circuit failure due to corrosion, cleaning must be performed after welding to ensure the reliability, electrical indicators, and working life of electronic equipment. Since military products must be cleaned, the cleaning process is particularly important for military products.

The traditional method of cleaning printed circuit boards is to use organic solvents. A mixed organic solvent composed of CFC-113 and a small amount of ethanol (or isopropyl alcohol) has a good cleaning ability for the residue of rosin flux, but due to the CFC-113 113 has a destructive effect on the atmospheric ozone layer and has been banned from use. The currently available non-ODS cleaning processes include water-based cleaning, semi-aqueous cleaning, and solvent cleaning. In addition, no-cleaning processes without cleaning can also be used. Follow we will introduce the water-based cleaning to you.

Water-based Cleaning Process

The water-based cleaning process uses water as the cleaning medium. To improve the cleaning effect, a small amount of surfactants, cleaning aids, corrosion inhibitors, and other chemical substances can be added to the water (generally the content is 2%-10%). According to the specific conditions of different types of pollution on the printed circuit board, additives can be added to the water-based cleaning agent to make the cleaning application wider. Water-based cleaning agents have a good dissolving effect on water-soluble dirt. Better cleaning results can be achieved when combined with physical cleaning methods such as heating, brushing, spraying, and ultrasonic cleaning. Adding surfactants to water-based cleaning agents can greatly reduce the surface tension of water, strengthen the penetration and spreading ability of water-based cleaning agents, and better penetrate into the gaps between closely arranged electronic components. Clean the dirt that has penetrated into the printed circuit board substrate.

The dissolution of water and the emulsification and dispersion of surfactants can also be used to remove the residues of synthetic active fluxes. It can dissolve and remove various water-soluble dirt and non-toxic materials such as synthetic resins and soluble dirt removal. When using rosin-based flux or water-based cleaning agents, add an appropriate saponifier. The saponifier is used to react with organic acids such as rosin acid in rosin and fatty acids in grease when cleaning printed circuit boards. A chemical that produces water-soluble fatty acid salts (soap). This is a common ingredient in many cleaning agents that clean flux and grease from printed circuit boards. Saponifying agents are usually alkaline inorganic substances such as sodium hydroxide, potassium hydroxide, and other strong bases, or they may be alkaline organic substances such as monoethanolamine. Commercial saponification agents generally also contain organic solvents and surfactants to clean and remove residues that cannot undergo saponification reactions. Saponification agents may cause corrosion to aluminum, zinc, and other metals on printed circuit boards, especially when the cleaning temperature is relatively high and the cleaning time is relatively long, it is easy to aggravate the corrosion. Therefore, corrosion inhibitors should be added to the formula. However, it should be noted that printed circuit boards containing components that are sensitive to alkaline substances should not be cleaned with water-based cleaning agents containing saponification agents.

Suppose ultrasonic cleaning is used in conjunction with the water-based cleaning process. In that case, the “cavitation effect” of a large number of tiny air bubbles generated during the propagation of ultrasonic waves in the cleaning solution can effectively remove insoluble dirt from the electronic circuit board. Considering the compatibility requirements of printed circuit boards, electronic components, and ultrasonic waves, the ultrasonic frequency used when cleaning printed circuit boards is generally around 40KHz.

Water-based Cleaning Process

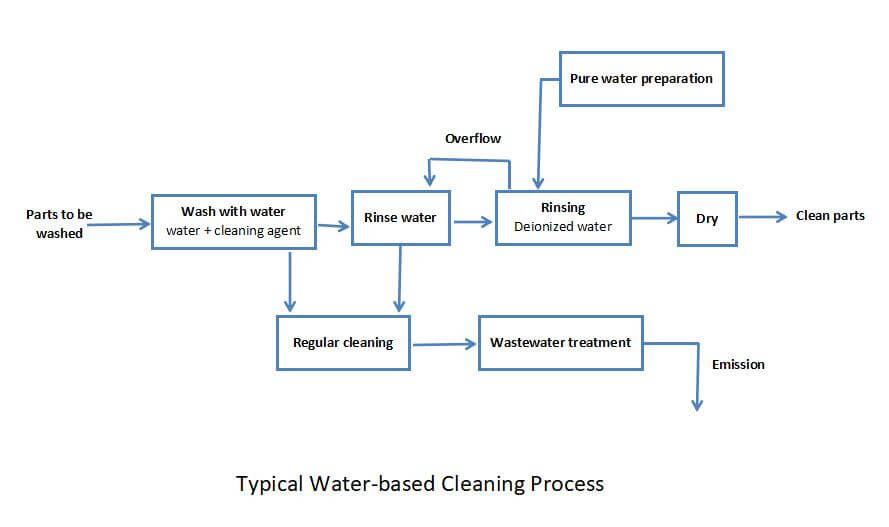

The water-based cleaning process includes cleaning, rinsing, and drying. First, use a water-based cleaning agent with a concentration of 2% to 10%, combined with physical cleaning methods such as heating, brushing, spraying, ultrasonic cleaning, etc. to batch clean the printed circuit boards, and then use pure water or ionized water (DI water) for 2 -3 rinses and finally hot air drying.

Why Water-based Cleaning is So Expensive?

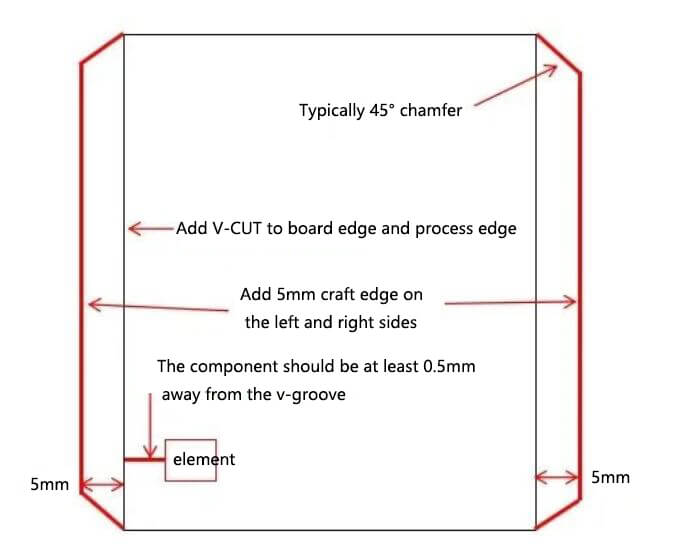

Water-based cleaning requires pure water for rinsing, which is why water-based cleaning is very expensive. Although high-quality water quality is a reliable guarantee for cleaning quality, in some cases lower-cost deionized water with a conductivity of 5um·cm is first used for rinsing, and finally high-purity deionized water with a conductivity of 18um·cm is used. A single rinse can also achieve good cleaning results. A typical water-cleaning process is shown in Figure 1. A typical process is: batch cleaning of electronic circuit boards with a water-based cleaning agent at a temperature of 55°C, combined with strong spray cleaning for 5 minutes, then rinsing with deionized water at 55°C for 15 minutes, and finally hot air at a temperature of 60°C Blow dry for 20 minutes.

To improve the utilization rate of water resources, tap water is used in the cleaning process, and deionized water is used in the rinsing tank. According to the literature, using tap water (hard water containing more ions) in pre-cleaning can greatly reduce production costs, and its stain-removal ability is no worse than soft water or deionized water.