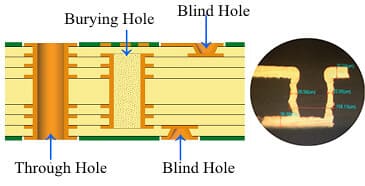

The common drilling holes in PCB are through hole(VIA), blind hole and embedded hole. What’s the meaning and characteristics of these three kinds of holes?

Via(Through Hole)

What is Via?

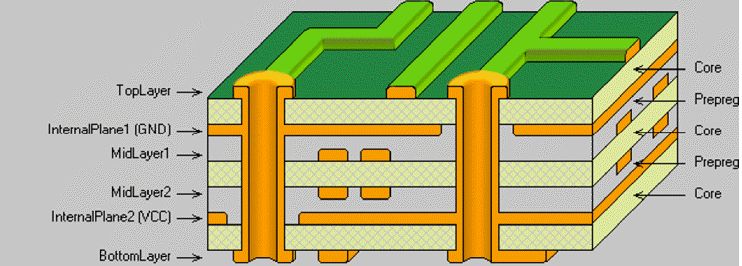

Via is a common hole and used to direct or connect copper foil lines between conductive patterns in different layers of the circuit board. Because PCB is formed by many copper foil layers stacked and accumulated, each layer of copper foil will be covered with an insulating layer, so that the copper foil layer cannot communicate with each other, and the signal link depends on the via, so it has the title of Chinese through hole.

The characteristics

In order to meet the needs of customers, the through hole of circuit board must be plugged. In order to change the traditional aluminum plug hole process, the white net is used to finish the resistance welding and plug hole on the board surface, so that its production is stable, the quality is reliable and the application is more perfect. The through hole is mainly used to connect and connect circuits. With the rapid development of electronic industry, higher requirements are put forward for the technology of PCB fabrication and surface mounting. The process of plug hole in the through hole is applied, and the following requirements should be met:

- Copper is available in the through hole, and the plug can be plugged when welding resistance is stopped.

- Lead and tin must be in the through hole. There must be no solder ink in the hole with certain thickness requirement (4um), which causes solder bead in the hole.

- The through hole must have the plug hole of welding ink, which is not transparent, and there shall be no tin ring, solder bead and leveling requirements.

Blind Hole

What is a blind hole?

A blind hole is to connect the outermost circuit in PCB with the adjacent inner layer with electroplated holes. Because the opposite side is not visible, it is called blind pass. At the same time, in order to increase the space utilization between PCB layers, blind holes are applied. That is, a through hole to a surface of the printed board.

Features

Blind holes are located on the top and bottom surfaces of the circuit board, with certain depth, which is used for the connection between the surface line and the inner circuit below. The depth of the hole usually does not exceed a certain ratio (aperture). This kind of production method needs to pay special attention to the drilling depth (Z-axis) to be right. If you don’t pay attention, it will cause the difficulty of plating in the hole, so it is almost no factory use. It can also drill the holes first when the circuit layer needs to be connected in advance, and then glue together. However, it needs to be more precise positioning and alignment device.

Embedded Hole

What is Embedded Hole?

Embedded hole is the connection between any circuit layer inside PCB but not connected to the outer layer, and also means that the through hole does not extend to the surface of the circuit board.

Features

In this process, it is impossible to use the method of drilling after bonding. It is necessary to drill holes in individual circuit layers. The local bonding of inner layer and then electroplating treatment can be done before all bonding. It is more time consuming than the original through hole and blind hole, so the price is also the most expensive. This process is usually used only for high density boards to increase the usable space of other circuit layers.

In PCB production process, drilling is very important and cannot be careless. Because drilling is to drill through the copper clad plate, to provide electrical connection, fixed device function. If the operation is not correct, there is a problem in the process of passing through the hole, the device cannot be fixed on the circuit board, and the light one will affect the use. If the weight is heavy, the whole board shall be discarded, so drilling is very important.