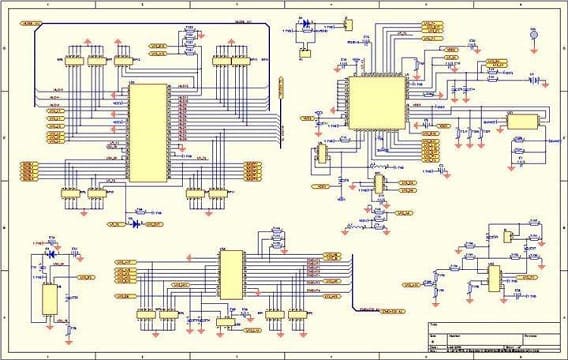

Printed circuit board design is based on circuit schematic diagram to realize the function required by circuit designer. PCB design mainly refers to layout design, which needs to consider the layout of external connection. When designing the PCB, it is important to note that each file should be connected as a whole at last, which is also of great significance to the future work. Because of the difference of software, some software may appear to be connected to the actual unconnected (electrical performance). If the relevant testing tools are not used to detect, in case of any problem, it will be late to find out when the board is finished. Therefore, the importance of doing in order is repeatedly emphasized, and we hope to attract attention.

The schematic is based on PCB design items, as long as the electrical connection is correct. Here I summarize some experiences and share them with you.

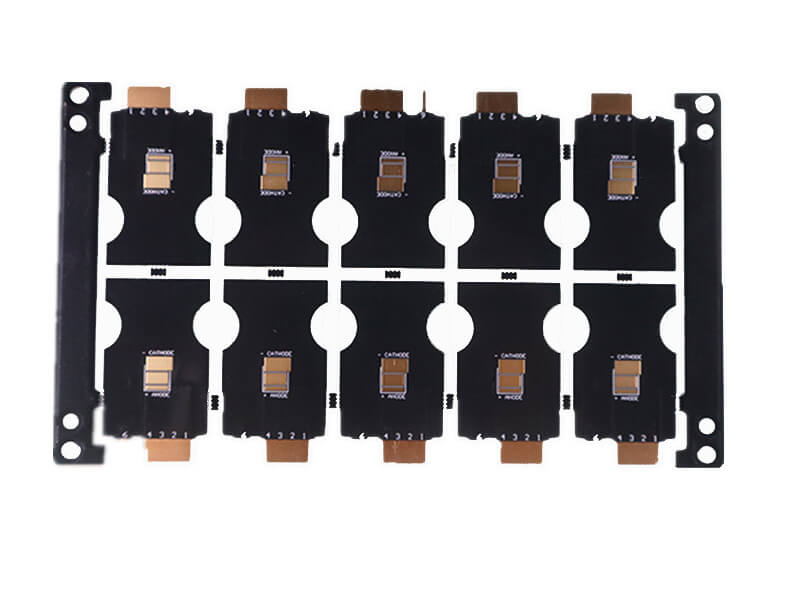

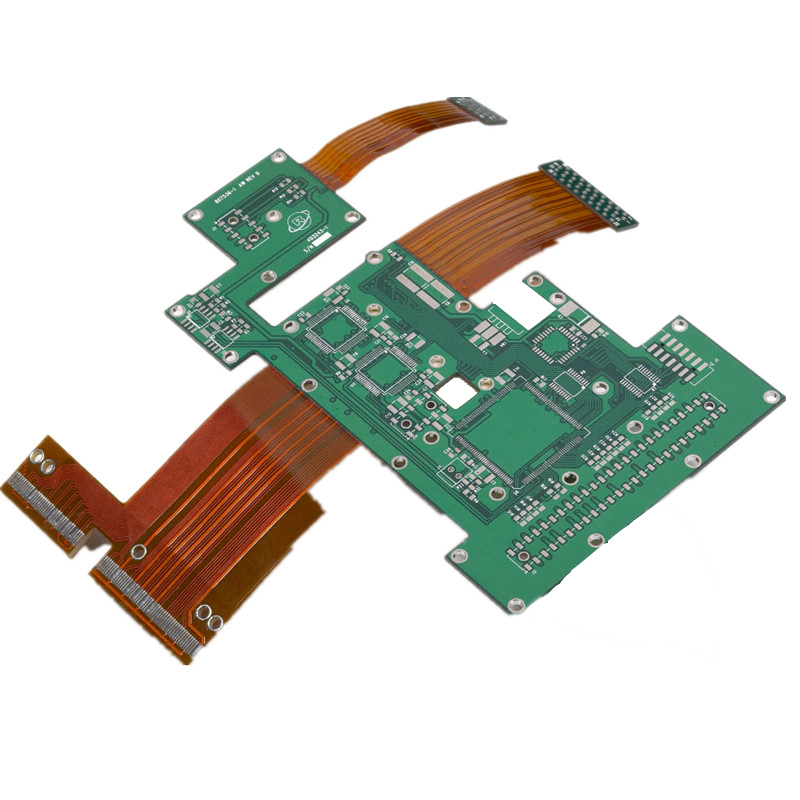

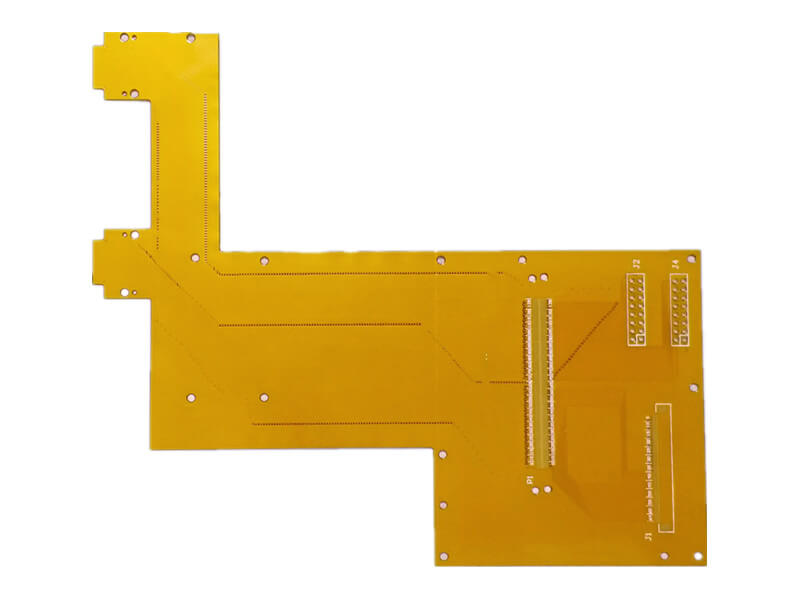

1. Make Physical Borders

The closed physical frame is a basic platform for the layout and routing of the components in the future. And it plays a constraint on the automatic layout. Otherwise the components coming from the schematic will be confused. You must pay attention to the accuracy because of the installation problems will be big in the future. One hand it is better to use circular arc in corner, on the other hand it can avoid sharp corner scratch workers. And it can reduce stress effect. One of my products always had some cases of PCB board breaking in the process of transportation before. I use are instead it and it would be better.

2. Introduction of Components and Networks

It should be very simple to draw the frame of components and network, but there are often problems here. It is necessary to carefully solve the errors according to the prompts, otherwise, it will take more effort later. The problems here are generally as follows:

The packaging form of components can not be found, component network problems, unused components or pins, and the comparison indicates that these problems can be solved quickly.

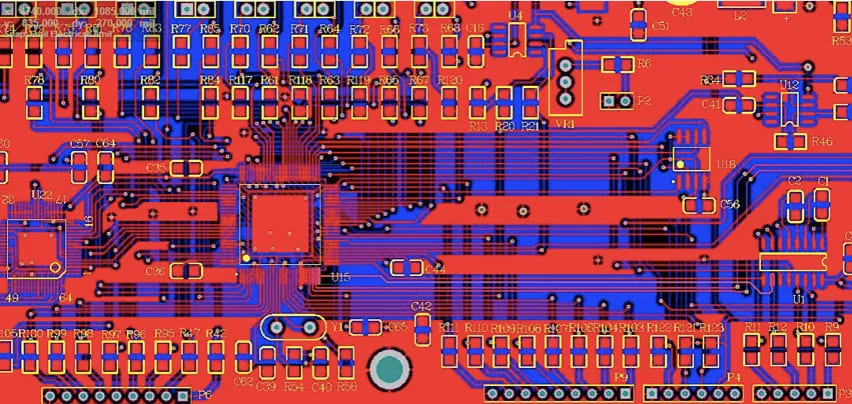

3. Layout of Components

The layout and routing of PCB components have a great influence on the life, stability and EMC of the products, which should be paid special attention to.

Generally speaking, there are some principles:

Placement Sequence

First, the components with fixed positions related to the structure, such as power socket, indicator light, switch, connection piece, etc., are placed. And then locked with the software lock function so that they will not be moved by mistake. Then place special components and large components on the line, such as heating elements, transformers, IC, etc. Finally, small devices are placed;

Pay Attention to Heat Dissipation

The layout of PCB circuit board should pay special attention to the heat dissipation. For high power circuits, the heating elements such as power pipes and transformers shall be distributed as far as possible to facilitate heat emission. Not to be concentrated in one place, nor to be too close to high capacitance to avoid premature aging of electrolyte.

4. Wiring

There are two ways of wiring: automatic wiring and interactive wiring. Before automatic wiring, the lines with strict requirements can be wired in advance. The side lines of input and output should avoid adjacent parallel to avoid reflection interference. If necessary, ground wire shall be added to isolate, and the wiring of two adjacent layers shall be vertical to each other, and parallel will easily lead to parasitic coupling.

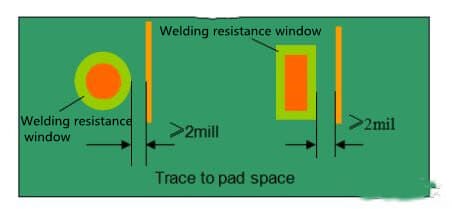

5. Adjustment And Improvement

After wiring is completed, it is necessary to adjust the text, individual components and wiring and apply copper (this work should not be too early, otherwise it will affect the speed and cause trouble to the wiring). It is also for the convenience of production, commissioning and maintenance.

Copper coating usually refers to filling the blank area left after wiring with large area copper foil, GND copper foil or VCC copper foil (but if short circuit is easy to burn down device, it is better to ground, unless it is not used to increase the conduction area of power supply to withstand large current before connecting VCC). The method of wrapping ground usually refers to the use of two ground wires (TRAC) to wrap a set of signal lines with special requirements to prevent it from being interfered or interfered with others.

If copper is used instead of ground wire, it is necessary to pay attention to whether the whole ground is connected, current size, flow direction and special requirements are required to ensure unnecessary errors are reduced.

6. Check The Network

Sometimes the network relationship of the board drawn is different from the schematic diagram due to misoperation or negligence. It is necessary to check the board. So after painting, you must not rush to hand over to the plate manufacturer. You should check it first, and then carry out the follow-up work.

7. Using Simulation Features

After these work is completed, software simulation can also be performed if time allows. Especially high frequency digital circuit, some problems can be found in advance, which greatly reduces the workload of debugging in the future.

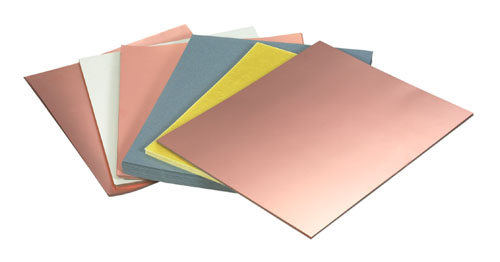

When the pcb design is finished, you might need pcb fabrication service. Contact us to get it in competitive price.