Many engineers still have such problems after debugging PCB. We summarize the steps of debugging. Before we introduce the first to third steps: detection before power on, power on test & other work in the debugging of electronic circuit. This article we will introduce last step failure during commissioning.

Step 5: Failure During Commissioning

To find out the cause of the fault carefully, it is not allowed to remove the line and re install it if the fault cannot be solved. Because the re installed line may still have various problems, if it is a problem in principle, even if the re installation can not solve the problem.

We should look for the fault, analyze the cause of the fault as a good learning opportunity, through which we can constantly improve our ability to analyze and solve problems.

1. Fault inspection ideas

For a complex system, it is not easy to find out the fault accurately in a large number of components and circuits. The general fault diagnosis process is based on the fault phenomenon, through repeated testing, making analysis and judgment, and gradually finding out the fault.

2. Failure phenomenon and causes

Common fault phenomenon, amplifier circuit has no input signal, but output waveform. The amplifier circuit has input signal, but it has no output waveform or abnormal waveform. The series voltage stabilized power supply has no voltage output, or the output voltage is too high to adjust, or the output voltage stabilizing performance is bad, and the output voltage is unstable. The oscillation circuit does not produce oscillation, the counter waveform is unstable, etc.

The reason for the failure is that the product is in failure after a period of time. It may be the component damage, short circuit and open circuit of the wiring, or the condition changes.

3. General methods for checking faults

- Direct observation

Check whether the instrument is selected and used correctly, and whether the power voltage level and polarity meet the requirements; Whether the polarity element pins are connected correctly, whether they are connected incorrectly, missed and touched. Whether the wiring is reasonable; Whether the printed board is short-term broken, whether the resistance capacitance has coking and cracking, etc. Power on to observe whether the components are hot and smoke, whether the transformer has coke smell, whether the electronic tube and oscillograph lamp filament are on, whether there is high voltage ignition, etc.

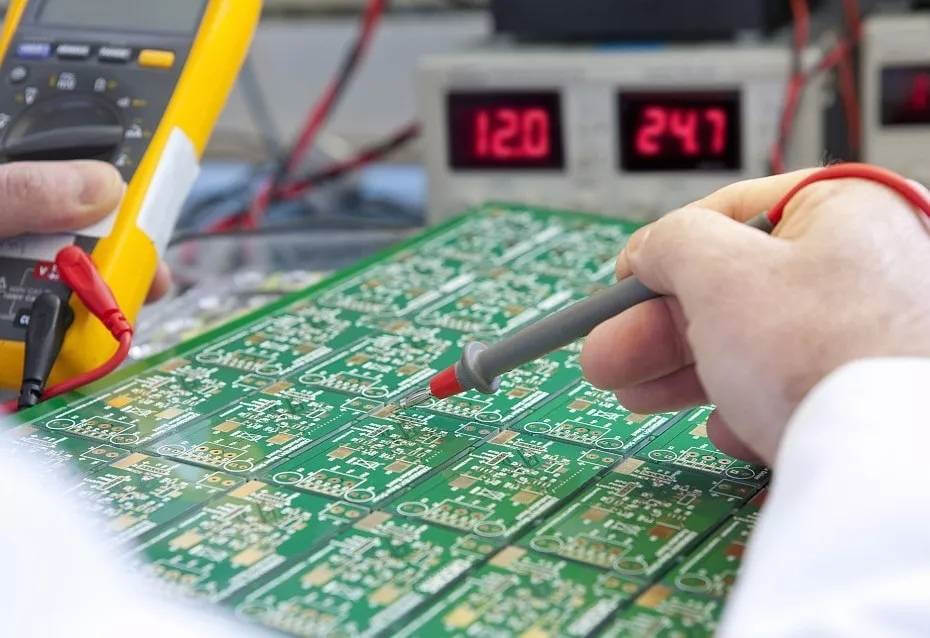

Check the static work point with a multimeter. The power supply system of electronic circuit, the DC working state of semiconductor triode and integrated block (including element, device pin, power supply voltage), resistance value in the circuit can be measured by multimeter. When the difference between the measured value and the normal value is large, the fault can be found through analysis.

By the way, static working points can also be measured by the input mode of oscilloscope “DC”. The advantages of oscilloscope are high internal resistance, can see the DC working state, signal waveform on the measured point, possible interference signal and noise voltage, etc., which is more conducive to the analysis of faults.

- Signal tracing method

For various complex circuits, a signal with a certain amplitude and appropriate frequency can be connected at the input end (for example, for multi-stage amplifiers, sinusoidal signal with F = 1000 Hz can be connected at its input end). The oscillograph is used to observe the change of wave shape and amplitude step by step from the front to the rear stage (or the contrary), and if any level is abnormal, the fault is at this stage. This is a way to check the circuit in depth. - Contrast method

If there is a problem in a circuit, the parameters of this circuit can be compared with the working state and the same parameters of normal circuit (or the current, voltage, waveform, etc.) theoretically analyzed. The abnormal condition in the circuit can be found out, and the cause of the fault can be analyzed and the fault point can be judged. - Part replacement method

Sometimes the fault is relatively hidden, and it can not be seen at once. If you have the same type of instrument as the fault instrument at hand, you can replace the parts, components, plug-in boards and other parts in the faulty instrument to reduce the fault range and further find the fault. - Bypass method

If there is parasitic oscillation, the capacitor with proper passenger capacity can be used to select the appropriate inspection point, and the capacitor can be temporarily jumper between the inspection point and the reference ground point. If the oscillation disappears, it indicates that the oscillation is generated in the nearby or pre-stage circuit. Otherwise, it will be in the back, and then move the checkpoint to find it. It should be pointed out that the bypass capacitance should be appropriate and should not be too large, as long as harmful signals can be eliminated. - Short circuit method

It is to take temporary short circuit to find out the fault. Short circuit method is most effective for checking open circuit fault, but it should be noted that short circuit method cannot be used for power supply (circuit). - Open circuit method

The method of open circuit is the most effective method to check short circuit fault. The method of breaking circuit is also a way to reduce the range of the fault suspect point gradually. For example, because a regulated power supply is connected to a circuit with fault, the output current is too large, we take the method of breaking a branch of the circuit in turn to check the fault. If the current returns to normal after the branch is disconnected, the fault occurs in this branch. - During actual commissioning

There are many ways to find out the cause of the fault, and only several common methods are listed above. The use of these methods can be flexibly mastered according to the equipment conditions and the fault conditions. For simple faults, one method can find the fault points, but for more complex faults, a variety of methods are needed to supplement and cooperate with each other to find out the fault points.

In general, the general practice of finding faults is:

- Use direct observation method to eliminate obvious faults.

- Check the static working point with Multimeter (or oscilloscope).

- Signal tracing is a simple and intuitive method which is widely used in various circuits, and is widely used in dynamic debugging.