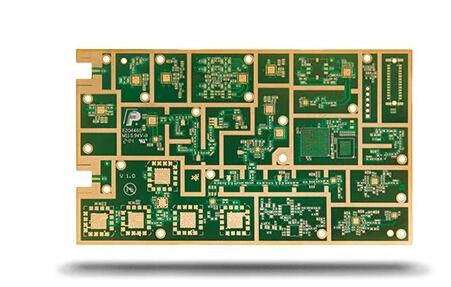

Item: Plasma gold removal oxidation technology

Technical Purpose: Use the cleaning machine to clean the gold surface of PCB, so as to solve the problem that the conventional horizontal cleaning line can not realize the cleaning of small-size boards.

Current Situation: The conventional horizontal cleaning line cannot realize the cleaning of small-size PCB. When the gold surface of PCB is discolored or polluted, it needs to be cleaned manually. The manual method is inefficient and the appearance quality cannot be guaranteed.

Technical Points

- Use CF+ O or Ar + h plasma gas cleaning to clean the gold surface of PCB.

- Plasma cleaning adopts static decontamination, which can avoid the damage of PCB gold surface such as collision and scratch in the decontamination process.

- Compared with the traditional horizontal line cleaning, plasma gold removal oxidation technology can realize the cleaning of ultra-small PCB and solve the problem of difficult cleaning of small PCB.

QDC change

| Item | Before Trial | After Trial |

| Q(quality) | / | The decontamination effect of the product after plasma treatment is remarkable. |

| D(efficiency) | Slow manual wiping speed | Batch treatment of gold surface pollution with high efficiency. |

| C(cost) | The comprehensive cost of manual wiping is high. | Eliminate the cost of manual wiping. |

Test Scheme

1. Cleaning principle of gold surface discoloration or pollution by plasma treatment

There are usually two reasons for discoloration or contamination of PCB gold surface. One is fingerprint grease or other organic residues; The other is gold surface oxidation. Gold is an inert metal, but the non gold substances on the surface of the weak area of the gold layer will contact with the outside world to produce chemical reaction, which will change the color of the gold surface. In this experiment, CF4 + O2 and Ar + H2 plasma gas treatment were used to remove gold oxidation.

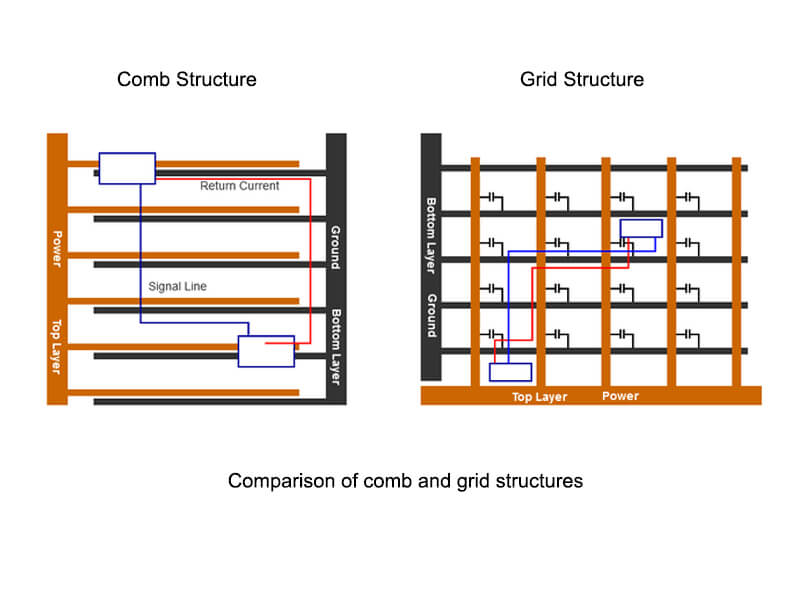

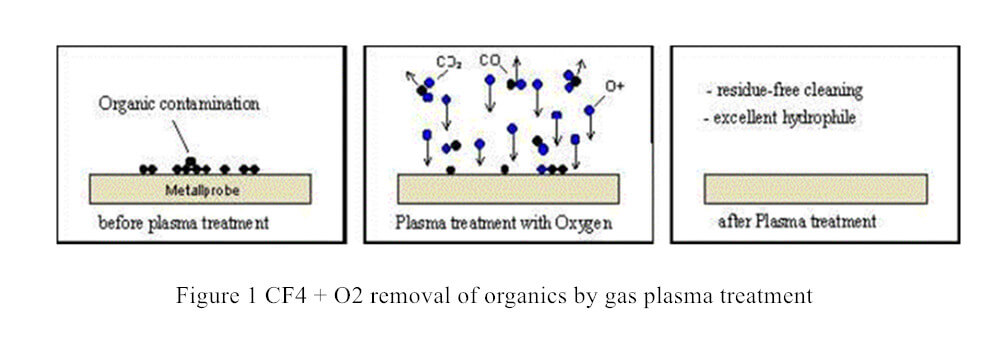

(1) CF4 + O2 gas plasma treatment

CF4 acts as an ionic stable gas and O2 acts as an ionization reaction gas. During plasma treatment, the object surface will be subjected to chemical bombardment, and the ultraviolet radiation generated by gas ionization will destroy the chemical bond of pollutants. Oxygen ions will react with bond breaking pollutants to generate carbon dioxide, which will be brought out by vacuum. Under the impact of high-energy ions, pollutants will also be broken and brought out by vacuum. Because plasma treatment can only penetrate several nanometers per second, it can not deal with too thick pollution layer, but it is especially suitable for the cleaning of fingerprint pollution. The schematic diagram is shown in Figure 1 below.

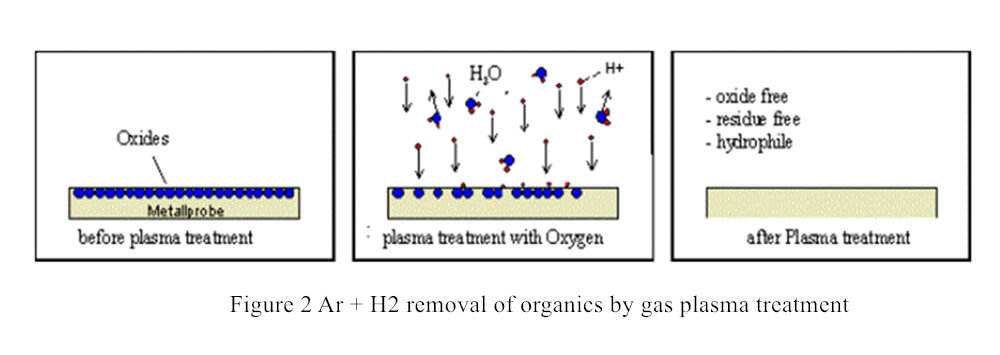

(2) Ar + H2 gas plasma treatment

In the process of plasma treatment, hydrogen is ionized and reacts with metal oxides to reduce the metal, and the other components are evaporated into water vapor. The schematic diagram is shown in Figure 2 below.

2. Experimental Design

According to the above plasma treatment principle, the plasma treatment test is carried out on the gold oxidized PCB in order to realize the gold surface cleaning. Under constant treatment power, temperature, humidity and vacuum, the main factors affecting plasma treatment are gas flow and treatment time. This test selects conventional plasma treatment, sets treatment power 4500W, temperature 35 ° C and vacuum 35, and tests CF4+ O2. , Ar + H2, the treatment effect of plasma gas in different gas flow and different treatment time is as follows.

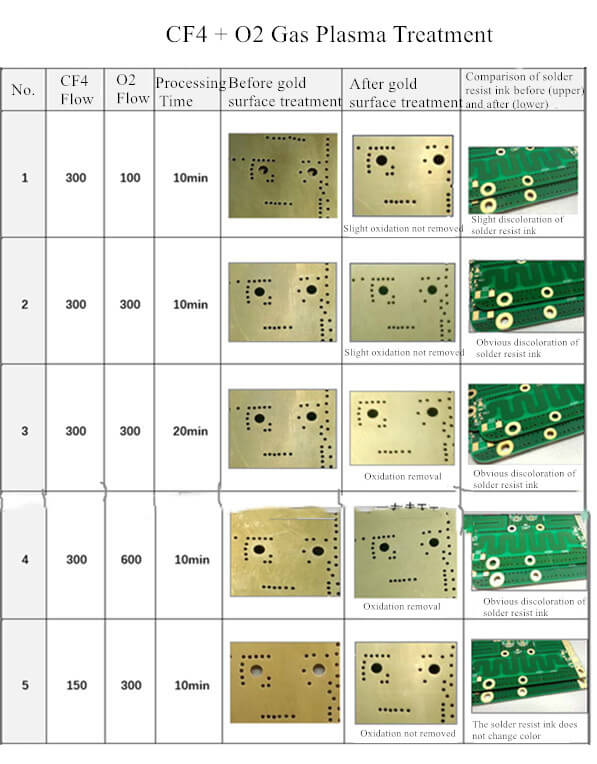

CF4 + O2 gas plasma treatment test

| No. | CF4 Flow | O2 Flow | Flow Mixing Ratio(CF4:O2) | Processing Time(min) |

| 1 | 300 | 100 | 3:1 | 10 |

| 2 | 300 | 300 | 1:1 | 10 |

| 3 | 300 | 300 | 1:1 | 20 |

| 4 | 300 | 600 | 1:2 | 10 |

| 5 | 150 | 300 | 1:2 | 10 |

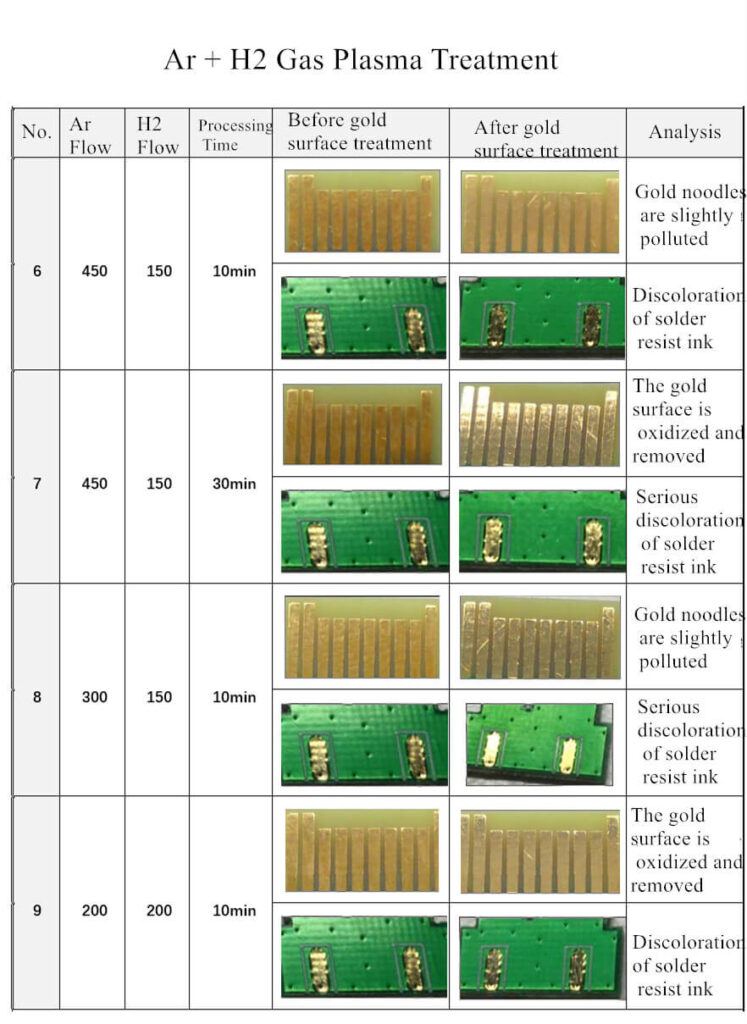

Ar + H2 gas plasma treatment test

| No. | Ar Flow | H2 Flow | Flow Mixing Ratio(Ar:H2) | Processing Time(min) |

| 6 | 450 | 150 | 3:1 | 10 |

| 7 | 450 | 150 | 3:1 | 30 |

| 8 | 300 | 150 | 2:1 | 10 |

| 9 | 200 | 200 | 1:1 | 10 |

3. Data Collection

After the completion of each group of tests, the data collected are as follows:

(1) data collection of de oxidation effect, and photos before and after the test.

(2) Collect the data of board ink appearance effect, and take photos before and after the test.

Acceptance index

| Item | Test Method | Inspection Standard |

| Deoxidation Effect | The golden face is free of oxidation and dirt. | Visual |

| Effect on ink | The ink does not fade, remains dark, and the characters are clear. | Visual |

Experimental Data

Summary

- Comparative experiments 2 and 3 show that the deoxidation effect increases with the increase of plasma treatment time under the same other conditions.

- Comparative tests 1, 2 and 4 show that the deoxidation effect increases with the increase of oxygen ratio under the same other conditions.

- Comparative tests 4 and 5 show that the deoxidation effect increases with the gas flow rate in the same proportion of gas and the same treatment time and improve.

- Compared with all tests, the discoloration of solder resist ink occurs when the deoxidation effect is achieved, which indicates that CF4+ O2 gas plasma treatment will cause serious attack on solder resist ink.

Summary

- Comparative tests 6 and 7 show that the deoxidation effect increases with the increase of plasma treatment time under the same other conditions.

- Comparative tests 6, 8 and 9 show that the deoxidation effect increases with the increase of hydrogen proportion under the same other conditions.

- Compared with all the tests, the discoloration of solder resist ink occurs when the deoxidation effect is achieved, which indicates that Ar+ H2gas plasma treatment will cause serious attack on solder resist ink.

Test result

- Use CF4+ O2gas plasma to treat the gold surface, CF4gas flow is 300, O2 gas flow is 600, and the treatment time is 10min, which can completely remove the gold surface pollution. The gold surface is treated with Ar + H2 gas plasma, the Ar gas flow is 200 and the H2 gas flow is 200, the treatment time is 10min, which can completely remove the gold surface pollution.

- Use CF4+ O2Or Ar + H2 plasma gas treatment can remove the gold surface pollution by adjusting the gas flow and treatment time, but the gold surface oxidation treatment will change the color of the solder resist ink, resulting in poor board surface appearance. Therefore, plasma gold removal oxidation can only be applied to PCB without solder resist ink.

- CF4+ O2and Ar + H2 Plasma can remove gold surface pollution, but AR is not a common gas of the company, and the company’s existing plasma cleaning machine cannot add a new air inlet, so Ar + H2 gas is not considered to remove gold surface oxidation.

Conclusion

With the plasma parameters of CF4 gas flow is 300, O2 gas flow is 600, treatment time is 10min, treatment power is 4500W, temperature is 35 ° C and vacuum is 35, the gold surface oxidation of non resistance welding ink and small-size PCB can be removed.