The opening design of SMT stencil shall consider the demoulding property of solder paste, which is determined by three factors:

- Width thickness ratio / area ratio of opening;

- Geometry of the opening sidewall;

- Finish of hole wall.

Among the three factors, the latter two factors are determined by the manufacturing technology of SMT stencil, and the former one we consider more.

Because of the good cost performance of laser SMT stencil, we focus on the opening design of laser SMT stencil.

First, we understand the aspect ratio and area ratio:

Width thickness ratio: the ratio of opening width to SMT stencil thickness.

Area ratio: the ratio of the opening area to the cross-sectional area of the hole wall

Generally speaking, to obtain good demoulding effect, the width thickness ratio should be greater than 1.5 and the area ratio should be greater than 0.66.

When to consider the width thickness ratio and when to consider the area ratio? Generally, if the opening length does not reach 5 times of the width, the area ratio should be considered to predict the release of solder paste, and the width thickness ratio should be considered in other cases.

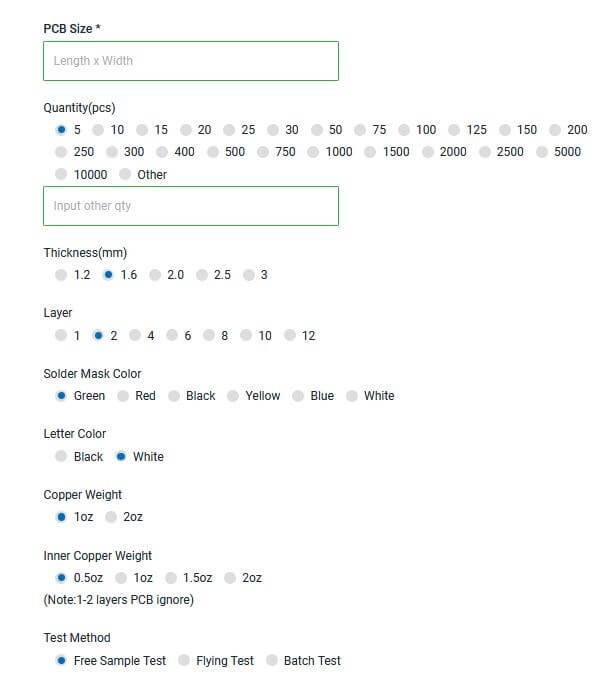

The following are examples of openings for some elements:

| Component Type | PITCH | Pad Width | Pad Length | Opening Width | Opening Length | Formwork Thickness | Width Thickness Ratio | Area Ratio |

| QFP | 0.635mm | 0.35mm | 1.50mm | 0.30-0.31mm | 1.45mm | 0.15-0.18mm | 1.7-2.1 | 0.69-0.85 |

| QFP | 0.50mm | 0.254mm | 1.25mm | 0.22-0.24mm | 1.20mm | 0.12-0.15mm | 1.5-2.0 | 0.62-0.83 |

| QFP | 0.43mm | 0.20mm | 1.25mm | 0.19-0.20mm | 1.20mm | 0.10-0.12mm | 1.6-2.0 | 0.68-0.85 |

| QFP | 0.30mm | 0.18mm | 1.00mm | 0.15mm | 0.95mm | 0.07-0.10mm | 1.5-2.1 | 0.65-0.93 |

| BGA | ∮1.27mm | ∮0. 8mm | ∮0. 75mm | 0.15-0.18mm | 1.0-1.25 | |||

| BGA | ∮1.0mm | ∮0.5mm | ∮0. 48mm | 0.12-0.15mm | 0.80-1.0 | |||

| uBGA | ∮0.8mm | ∮0.4mm | ∮0. 40mm | 0.12-0.15mm | 0.67-0.83 | |||

| uBGA | ∮0.8mm | ∮0.4mm | 0. 38mm | 0. 38mm | 0.12-0.15mm | 0.63-0.79 | ||

| uBGA | ∮0.5mm | ∮0.25mm | 0. 28mm | 0. 28mm | 0.08-0.10mm | 0.70-0.86 | ||

| 0402 | 0.5mm | 0.65mm | 0.48mm | 0.635mm | 0.10-0.12mm | 1.4-1.37 | ||

| 0201 | 0.25mm | 0.40mm | 0.235mm | 0.38mm | 0.08-0.10mm | 0.73-0.91 |

- The width W of the strip shall be: 0.3mm ≤ w ≤ 2.0mm

- The diameter of the round hole is:

| Component | 0603 | 0805 | 1206 | 3212 |

| Diameter (d)mm | 0.36 | 0.55 | 0.8 | 1.0 |

- The thickness of rubber printing SMT stencil is generally 0.15 mm ~ 0.2mm

- Fine pitch IC / QFP, in order to prevent stress concentration, it is best to round corners at both ends; BGA with square holes and 0402 and 0201 pieces are the same.

- It is better to select the concave opening method for the anti tin bead opening method of sheet components, which can effectively prevent the component tombstone.

- When designing the SMT stencil, the opening width shall ensure that at least 4 maximum tin balls can pass smoothly.